Laser Distance Measurement Sensors for Liquid Level Detection

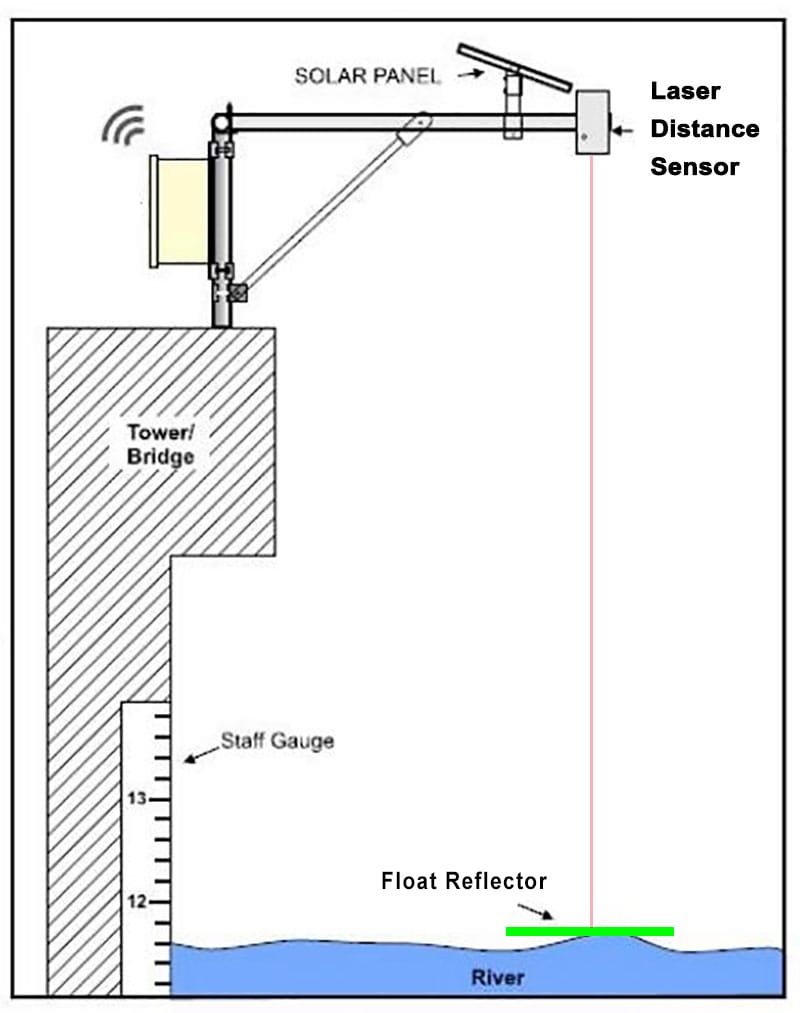

In industries ranging from water treatment to chemical processing, accurate and reliable liquid level measurement is critical for ensuring operational efficiency and safety. Laser distance measurement sensors, commonly known for their precision in distance measuring, have found significant applications in liquid level detection. These sensors, when combined with a float reflector, offer a non-contact, highly accurate method for measuring liquid levels, making them an invaluable tool in industrial settings.

Understanding How Laser Distance Measurement Sensors Work in Liquid Level Measurement

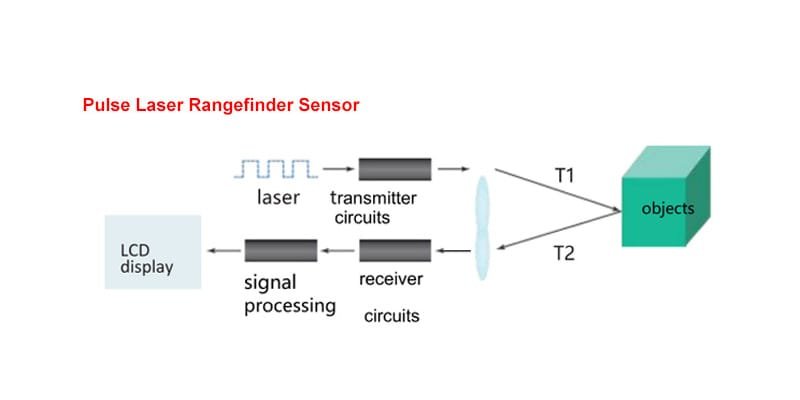

The basic working principle of laser distance measurement sensors for liquid level detection involves emitting a laser beam from a sensor mounted above the liquid surface. A float reflector, placed on the water surface or liquid surface, reflects the laser beam back to the sensor. The sensor measures the time taken for the laser to return, and calculates the distance accordingly. This distance is then used to determine the liquid level.

The benefits of this approach are clear:

- Non-contact measurement reduces the risk of contamination or damage to both the sensor and the liquid being measured.

- The high accuracy of laser sensors, typically within ±1–3 mm, ensures precise and reliable readings.

- Suitable for measuring liquid levels in harsh environments such as tanks with high vapor content or aggressive chemicals, where other methods may fail.

Advantages of Laser Distance Measurement Sensors in Liquid Level Monitoring

Laser distance sensors bring multiple benefits to liquid level monitoring applications:

1. Non-Contact and Safe Measurement

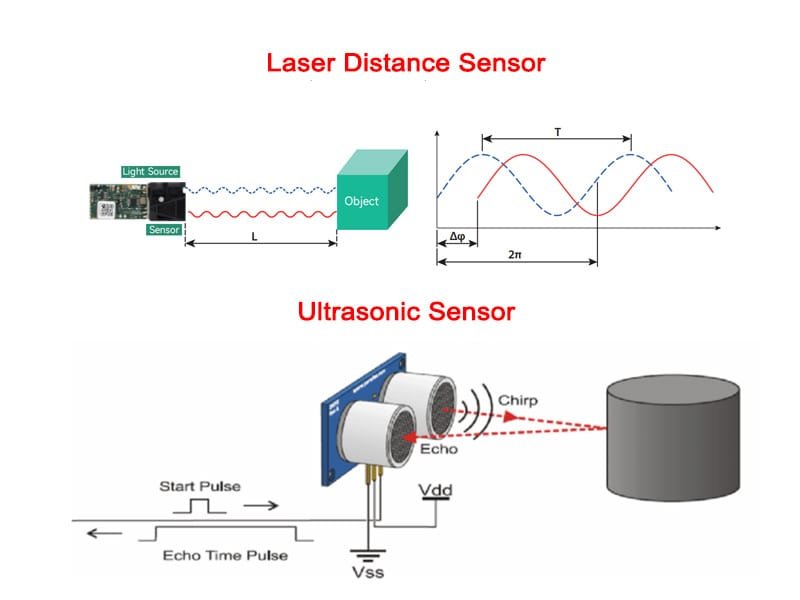

In industries that deal with hazardous liquids, the need for non-contact measurement is crucial. Unlike traditional methods such as ultrasonic or capacitive sensors, laser sensors do not need to be in direct contact with the liquid. This is especially important when measuring aggressive or toxic substances, ensuring both safety and accuracy without the risk of contamination.

2. High Accuracy and Precision

Laser distance sensors are designed for highly accurate measurements, with typical deviations of only a few millimeters. This high level of accuracy ensures that liquid levels are monitored with precision, reducing the risk of overflow or underfill in tanks, which could result in operational inefficiency or safety concerns.

3. Reliable Performance in Harsh Conditions

Laser sensors are less susceptible to the environmental factors that often interfere with ultrasonic sensors. For example, ultrasonic sensors may have trouble measuring in areas with high humidity, foam, or temperature fluctuations. In contrast, laser distance sensors can maintain accurate readings even in these challenging conditions, offering more reliable performance over time.

4. Wide Application Range

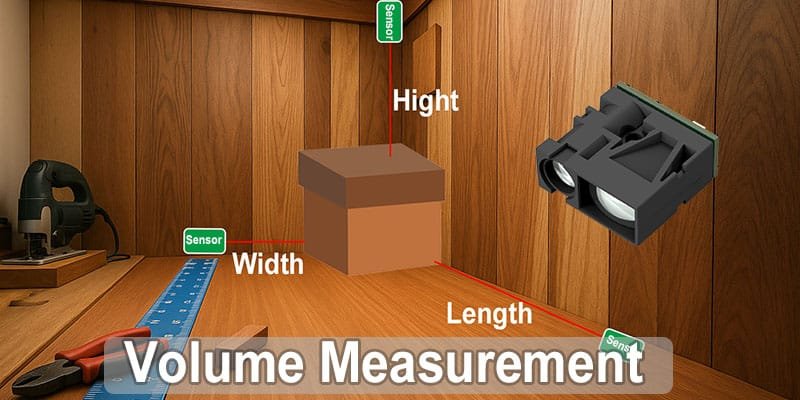

Laser sensors are versatile and can be used in a wide range of liquid types, from clear water to viscous liquids or even liquids with foam. Additionally, laser distance sensors can measure liquid levels in various types of tanks, including open tanks, closed tanks, and containers with narrow openings, offering greater flexibility in installation and application.

5. Minimal Maintenance Requirements

Due to their non-contact nature, laser distance measuring sensors generally require very little maintenance compared to other sensor types, such as ultrasonic sensors, which may suffer from buildup of dirt or condensation on the sensor face. This lower maintenance burden reduces operational downtime and costs.

Laser Distance Measurement Sensors vs. Ultrasonic Sensors

While both laser distance sensors and ultrasonic sensors are used for liquid level measurement, their performance in certain conditions differs significantly. Understanding these differences can help in selecting the right technology for a particular application. Learn more about Laser vs Ultrasonic Distance Sensor

Comparison of Laser and Ultrasonic Sensors

| Feature | Laser Distance Measurement Sensors | Ultrasonic Sensors |

|---|---|---|

| Measurement Accuracy | ±1-3 mm | ±10 mm or more |

| Response Time | Fast and accurate | Slower, especially in larger tanks |

| Susceptibility to Environmental Factors | Resistant to steam, humidity, and temperature | Affected by steam, foam, and temperature |

| Beam Angle | Narrow, ideal for confined spaces | Wide, which can lead to inaccurate readings |

| Surface Reflectivity Impact | Less affected by surface properties | Highly affected by liquid surface conditions |

| Maintenance Requirements | Low, no contact with liquid | Higher, due to potential buildup on sensors |

Why Choose Laser Distance Sensors Over Ultrasonic Sensors?

- Accuracy and Stability: Laser distance sensors provide more accurate and stable readings in applications where high precision is necessary, while ultrasonic sensors may struggle with foam, vapor, or fluctuating temperatures.

- Better for Harsh Environments: For industries like oil and gas, where liquid levels can fluctuate dramatically, laser distance measuring sensors perform reliably in extreme conditions where ultrasonic sensors often fail.

- Non-Contact Operation: Laser sensors are ideal for systems where contamination risks need to be minimized, as they don’t require contact with the liquid surface, unlike ultrasonic sensors, which may need to be placed closer to the liquid.

Application Examples of Laser Distance Measurement Sensors for Liquid Level Detection

Laser distance sensors are increasingly used in industries for liquid level measurement, including:

- Water Treatment: Ensuring that water storage tanks maintain the correct levels without contamination or overflow.

- Oil and Gas: Measuring fuel and oil levels in large tanks, with an added benefit of working in hazardous conditions.

- Chemical Processing: Monitoring the levels of chemicals in tanks, where ultrasonic sensors may struggle due to vapor or foam.

- Food and Beverage: Liquid level detection in tanks storing beverages or syrups, where hygienic, non-contact measurement is essential.

Conclusion: The Future of Liquid Level Measurement

As industrial needs evolve, the demand for precision, reliability, and safety in liquid level monitoring continues to grow. Laser distance measurement sensors, with their high accuracy, non-contact operation, and ability to withstand harsh conditions, represent the future of liquid level measurement.

By opting for a distance measuring sensors like a laser sensor, industries can improve operational efficiency, reduce maintenance costs, and ensure more accurate and reliable liquid level monitoring — ultimately leading to safer, more efficient processes.