Application of laser distance sensor in industrial automation

Laser distance sensor in industrial automation is revolutionizing the way industries operate by providing highly accurate, real-time measurements that enhance efficiency, precision, and safety. Whether it’s optimizing production lines or ensuring smooth material handling, laser distance sensors are essential in a wide range of industrial applications. Below, we explore the key industrial automation scenarios where laser distance sensors make a significant impact, along with the advanced features that make them suitable for even the most demanding environments.

1. Robotics and Manufacturing

In the field of robotics, laser distance sensor in industrial automation ensures precise positioning and motion control. These sensors enable robotic arms to perform tasks like assembly, packaging, and material handling with unmatched precision. With a measurement accuracy down to millimeters, they allow robots to operate with high efficiency and minimal errors, even in complex environments. The rugged designs of these sensors, including IP-rated protective housings, make them ideal for use in harsh factory floors, where dust, humidity, and temperature fluctuations can often compromise other sensors’ performance.

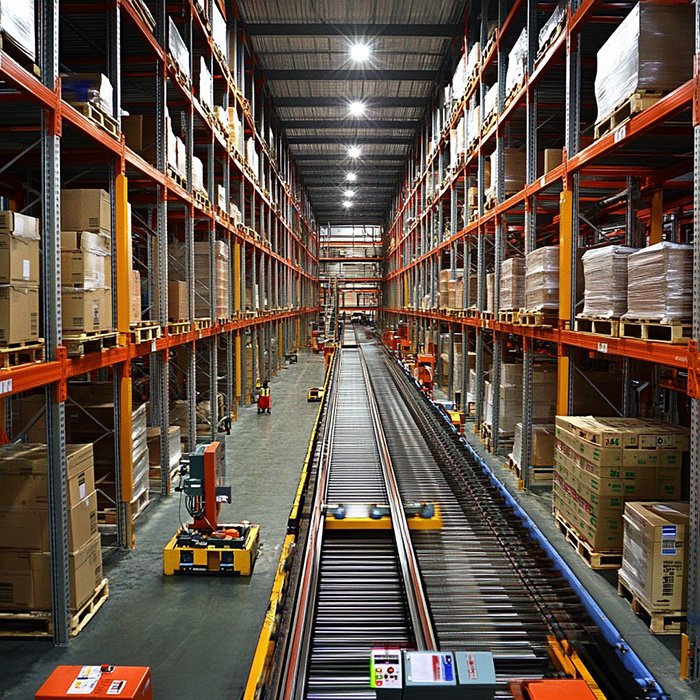

2. Industrial Laser Distance Sensor for Conveyor Systems and Material Handling

Laser distance sensor in industrial automation is crucial for optimizing conveyor systems, where accurate tracking of materials is vital. These sensors detect the precise distance between products, ensuring smooth transport and preventing jams. With a measurement range that extends across long distances, laser distance sensors monitor the position of materials across the production line. Models with IP protection ratings offer extra durability, making them resilient to exposure to dust and water, which are common in material handling applications.

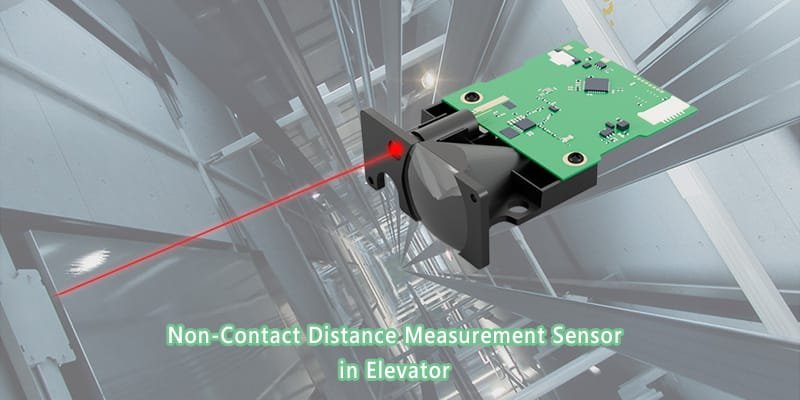

3. Elevators and Vertical Transport

Laser distance sensor in industrial automation also plays a critical role in vertical transport systems, such as automated elevators and lifts. These sensors precisely measure the height and distance between floors, ensuring accurate elevator positioning. This is especially important in industries that rely on automated lifting systems for efficient material transport in warehouses or manufacturing facilities. Laser distance sensors with millimeter-level precision ensure that elevators move smoothly between floors, while those with IP-rated enclosures protect against environmental challenges like moisture and dust.

4. Quality Control and Inspection

Laser Distance Sensor Industrial is widely used for quality control in manufacturing processes. Whether measuring the dimensions of components during production or inspecting alignment in assembly lines, these sensors provide highly accurate data. Their millimeter-level precision ensures that every product meets the exact specifications required. Additionally, laser distance sensors with IP-rated housings are perfect for quality control applications in industries where the environment is harsh, such as automotive or electronics manufacturing, where dust, dirt, and chemicals are prevalent.

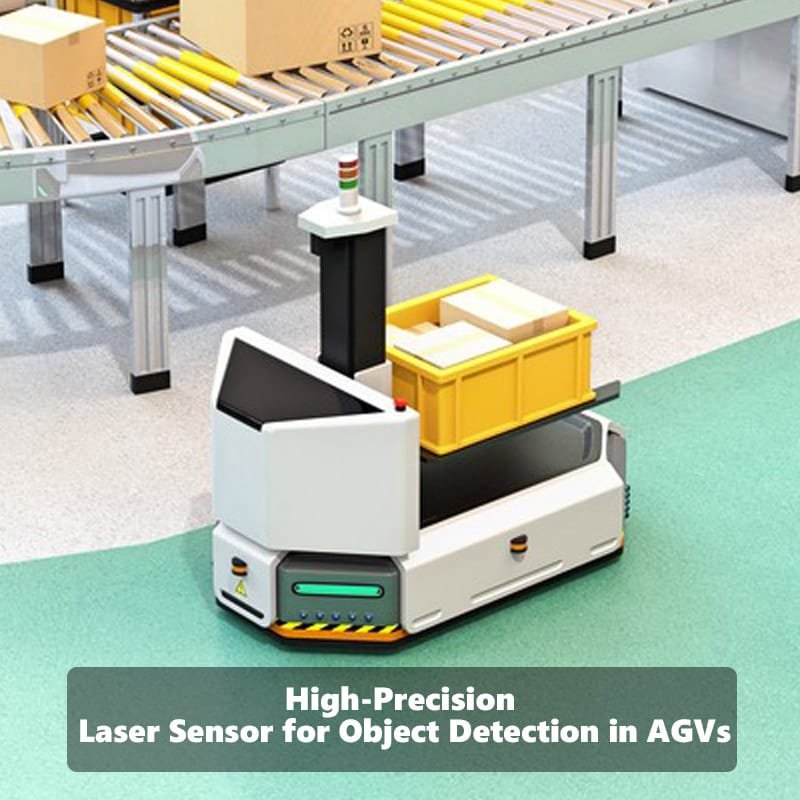

5. Automated Guided Vehicles (AGVs)

Industrial Laser Distance Sensor in automation is integral to the safe operation of Automated Guided Vehicles (AGVs), which are used for material transport in factories and warehouses. These sensors help AGVs measure the distance to obstacles, allowing them to navigate autonomously and avoid collisions. With a robust design and IP-rated protective features, laser distance sensors ensure AGVs can operate in demanding environments, such as warehouses with fluctuating temperatures or factory floors with high levels of dust and moisture.

6. Precise Positioning for CNC Machines

In CNC (Computer Numerical Control) machines, Industrial Laser Distance Sensor ensures the accurate positioning of tools and workpieces. These sensors provide precise feedback on the distance between the machine tool and the material, enabling precise cuts, drills, and engravings. The ability to measure down to the millimeter level is crucial in industries requiring high-precision manufacturing, such as aerospace and automotive. The IP-rated versions of these sensors provide the added benefit of withstanding coolant sprays and other industrial liquids in CNC machining environments.

7. Predictive Maintenance and Asset Management

Industrial Laser Distance Sensor can also be integrated into predictive maintenance systems. By continuously monitoring the position and alignment of machine parts, these sensors can detect misalignments or wear and tear before they lead to equipment failure. This early warning system helps prevent costly downtime and extend the lifespan of machinery. With features like high IP protection and the ability to operate in extreme temperatures, laser distance sensors ensure reliable performance in even the toughest industrial environments.

Key Product Features

- Millimeter-Level Accuracy: Laser distance sensors offer high-precision measurements, typically down to millimeters, ensuring the accuracy needed for demanding industrial tasks.

- IP Protection: Many models are equipped with IP-rated protective enclosures that safeguard the sensor from dust, moisture, and other environmental factors, making them ideal for use in harsh industrial environments.

- Wide Measurement Range: These sensors are capable of measuring over long distances, which is crucial for applications such as robotic arm positioning, conveyor systems, and warehouse automation.

- Robust and Durable: Laser distance sensors are designed to withstand the challenging conditions often found in industrial settings, including high temperatures, humidity, dust, and vibration.

- Versatility: Laser distance sensors are suitable for a wide range of industrial applications, from robotics and material handling to quality control and predictive maintenance, ensuring seamless integration into automated systems.

Conclusion

The application of laser distance sensor in industrial automation is vital for improving precision, efficiency, and safety across various industries. Whether used in robotics, conveyor systems, or automated vehicles, these sensors offer millimeter-level accuracy and are built to withstand even the harshest conditions. With their IP-protected housings and robust designs, laser distance sensors are the ideal choice for optimizing industrial automation systems, reducing downtime, and enhancing operational performance.