LDL 20Hz High Accuracy Laser Distance Sensor

– Precision Measurement for Industrial Applications

The LDL 20Hz High Accuracy Laser Distance Sensor is a state-of-the-art measurement solution designed for industrial automation, robotics, and precision inspection. Utilizing phase-based laser ranging technology with a Class II laser (620-690nm), this sensor achieves 1mm accuracy within a 10-meter measurement range. Its 20Hz high-speed sampling rate ensures real-time and highly stable measurements, making it ideal for applications requiring fast, precise, and reliable distance detection.

Key Features

✔ High Accuracy: ±1mm precision for stable and repeatable measurements

✔ Phase-Based Laser Ranging: Ensures superior performance in industrial applications

✔ 20Hz Fast Measurement Frequency: Ideal for real-time dynamic tracking

✔ Class II Laser (620-690nm): Safe, visible red laser for easy alignment

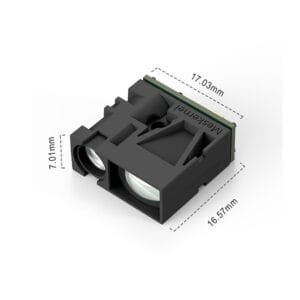

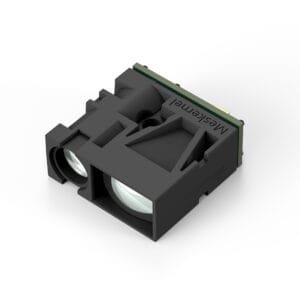

✔ Compact & Robust Design: Easy integration into automation and robotics systems

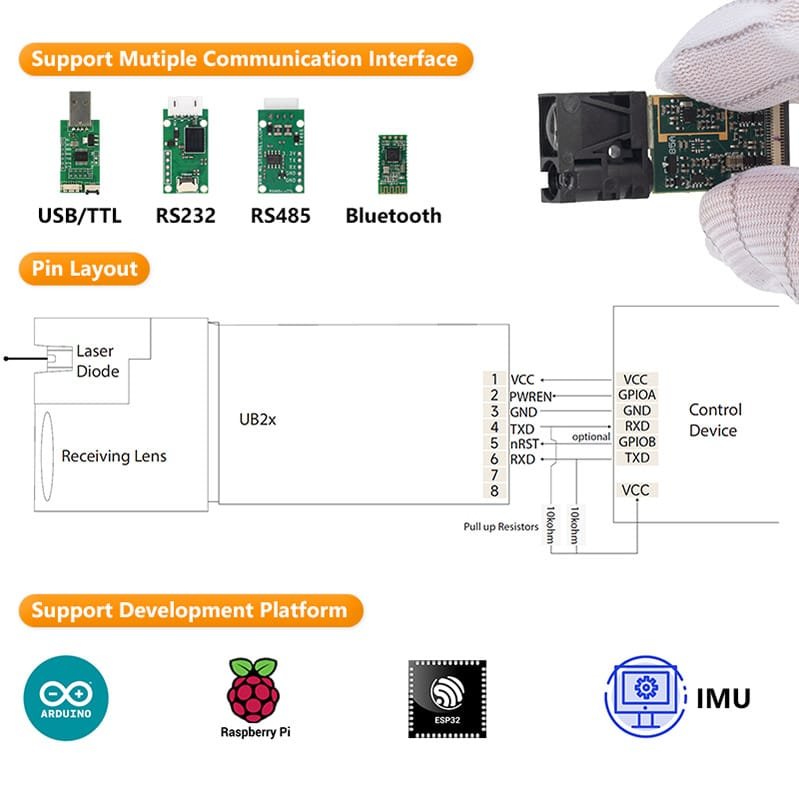

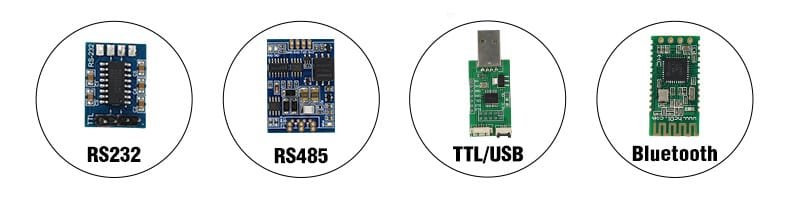

✔ Multiple Communication Interfaces: RS232, RS485, TTL, and CAN for seamless connectivity

Technical Specifications

Accuracy | ±1mm |

Measurement Units | Meter/Inch/Feet |

Measure Distance | 0.03-5/10/20 meters |

Measure Time | 0.3~4 seconds |

Frequency | 3/10/20Hz |

Laser Type | 620nm-690nm, <1mW Red laser |

Laser Class | Class II |

operating Temperature | 0-40 ℃ (32-104 ℉ ) |

Storage Temperature | -25~60 ℃ (-13~140 ℉) |

Interface | UART/RS485/RS232/Bluetooth |

Voltage | DC 2.5~3.3V |

Size | 42*17*7mm |

Weight | 4g |

Advanced Phase-Based Laser Ranging for Superior Accuracy

The LDL laser distance sensor utilizes 620-690nm phase laser ranging technology, which calculates distance by measuring the phase shift of the reflected laser signal. This method provides exceptional accuracy and stability, even in industrial environments with varying surface materials and ambient lighting conditions.

High-Speed 20Hz Measurement for Real-Time Applications

With a 20Hz measurement frequency, the LDL laser distance sensor is capable of real-time distance tracking, making it perfect for high-speed production lines, robotic navigation, and automated quality control. Whether monitoring moving objects or ensuring precise positioning, this sensor delivers instant and reliable data.

Class II Laser – Safe and Visible for Easy Alignment

The LDL sensor employs a Class II laser (620-690nm visible red laser), which is safe for industrial use and easy to align during setup. Unlike infrared lasers, the visible red laser beam allows for quick positioning and calibration, reducing installation time and improving usability.

Seamless Integration with Industrial Systems

The LDL sensor supports multiple industrial communication protocols, including:

✔ RS232 / RS485 – Reliable serial communication for industrial applications

✔ TTL – Low-power interface for embedded systems

✔ CAN – Real-time data transmission for automation and robotics

This ensures easy connectivity with PLC controllers, robotic systems, and industrial monitoring devices.

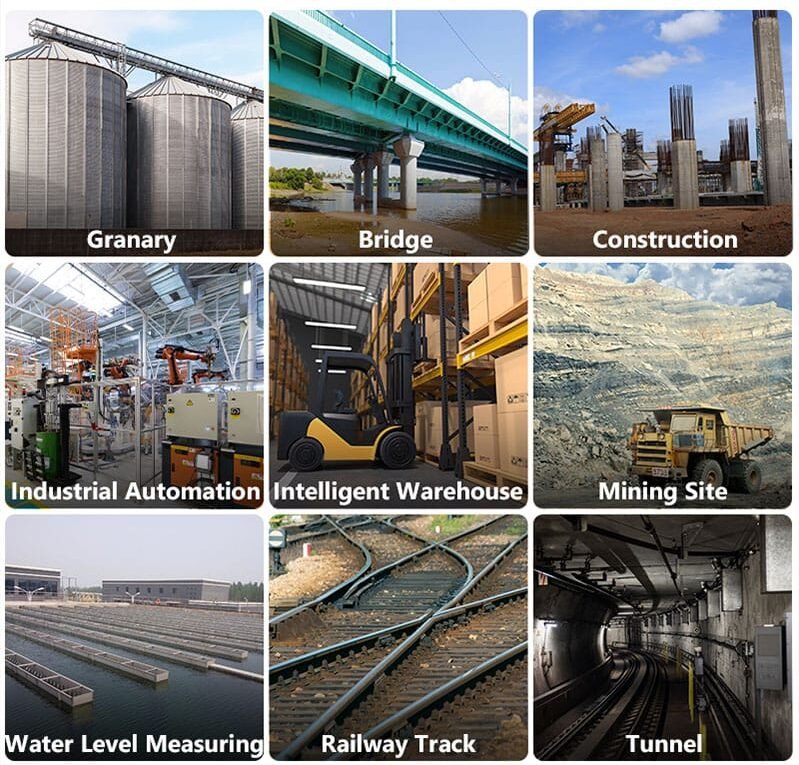

Applications of the LDL Laser Measurement Sensor

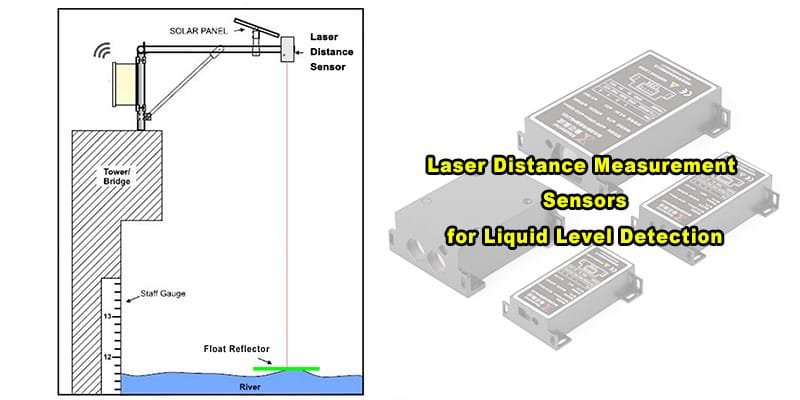

- Industrial Automation: Precision positioning, conveyor belt monitoring, automated inspection

- Robotics & AGVs: Obstacle detection, SLAM navigation, robotic arm positioning

- Quality Control & Inspection: Non-contact measurement, product dimension verification

- Logistics & Warehousing: Package measurement, automated sorting, level detection

- Medical & Research Applications: Laboratory automation, precision device positioning

Recommended Products

Looking for more laser distance sensor options? Check out our:

- Long-Range Laser Rangefinder Sensor: Up to 3000m range for industrial and outdoor applications

- Industrial Laser Distance Sensor: Built for harsh industrial environments, providing reliable and stable performance for automation and control systems.

- High-Frequency Laser Range Sensor: 500Hz+ fast measurement, ideal for high-speed motion tracking

The LDL 20Hz High Accuracy Laser Distance Sensor is the perfect choice for precision measurement applications, combining high-speed data acquisition, industrial reliability, and ease of integration. Contact us today to learn more!