Revolutionizing of Laser Distance Sensor in Smart Logistics

Brief Description:

The widespread application of precision laser distance sensor in smart logistics improves the automation levels in storage, transportation, and sorting processes, ensuring precise and efficient operations while reducing labor costs. This technology helps enterprises achieve full-process digital management, enhancing the intelligence of storage and logistics systems.

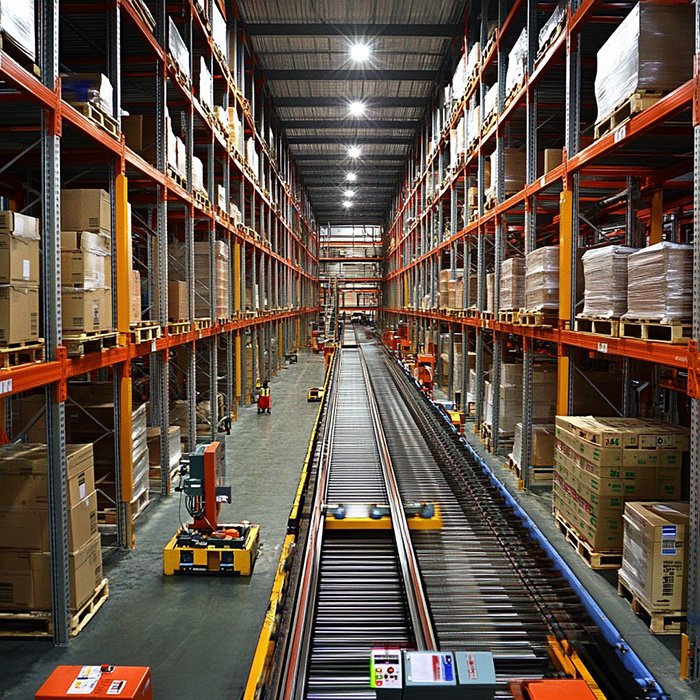

1. Introduction: The Intelligent Transformation of the Logistics Industry

With the rapid development of e-commerce and supply chain management, traditional logistics modes face unprecedented challenges, such as low efficiency in goods handling, high labor costs, and frequent errors. Smart logistics systems are becoming the future trend, with laser distance sensors playing a crucial role in warehouse management, automated transportation, and sorting systems.

2. Application in Smart Warehouse Management

Efficient Storage and Retrieval:

Laser distance sensors enable automated warehouses to accurately locate and manage goods. In storage and retrieval processes, sensors detect the position and distance of items on shelves, ensuring that automated equipment like stackers or AGVs (Automated Guided Vehicles) perform precise handling tasks. This non-contact measurement reduces manual intervention and improves operational efficiency.

Smart Inventory Management:

Using laser Precision Laser Distance Sensor, warehouse management systems can track inventory status in real-time, automatically update stock levels, and issue replenishment alerts. Compared to traditional manual inventory checks, smart inventory management is more efficient and accurate, avoiding operational issues caused by stock shortages or surpluses.

3. Role in Sorting Systems

Fast and Accurate Sorting:

Laser sensors detect the position and dimensions of packages on conveyor belts and direct them to different sorting outlets based on predefined routes. Even in high-load logistics centers, sensors ensure goods are efficiently and accurately delivered to their destination areas.

Automatic Error Correction and Anomaly Detection:

Sensors monitor the movement of packages during transit, correcting misalignments or anomalies to prevent conveyor belt blockages and product damage. By providing real-time feedback to the logistics management system, sensors enhance sorting accuracy and system stability.

4. Safety Assurance in Transportation

Distance Monitoring in Automated Transport:

Laser Distance Sensor in Smart Logistics help automated logistics vehicles and unmanned delivery vehicles sense the distance to obstacles, ensuring safe travel. Vehicles can automatically slow down or avoid obstacles based on distance information, enhancing the safety of unmanned equipment.

Collision Prevention and Product Protection:

In handling or stacking processes, laser sensors monitor the distance between items to prevent collisions and damage. This precise control ensures smoother transportation and improves customer satisfaction.

5. Case Study: Implementation at a Large Logistics Center

After implementing Precision Laser Distance Sensor in a warehouse center, a globally recognized logistics enterprise improved goods handling efficiency by 30%. The automated system operates 24/7, with inventory tracking and sorting errors reduced to 0.5%. AGVs use sensors to detect their environment, autonomously plan paths, and minimize manual intervention, demonstrating the significant value of laser sensor technology in practical applications.

Conclusion: Laser Sensors Empowering Future Smart Logistics

Laser Distance Sensor in Smart Logistics greatly enhance operational efficiency, reduce costs, and minimize human errors in smart logistics systems. As artificial intelligence and IoT technologies evolve, laser sensors will continue to drive intelligent transformation in the logistics industry, providing enterprises with more innovative opportunities and competitive advantages.