Application of Laser Distance Sensor in Construction Industry

Brief Description:

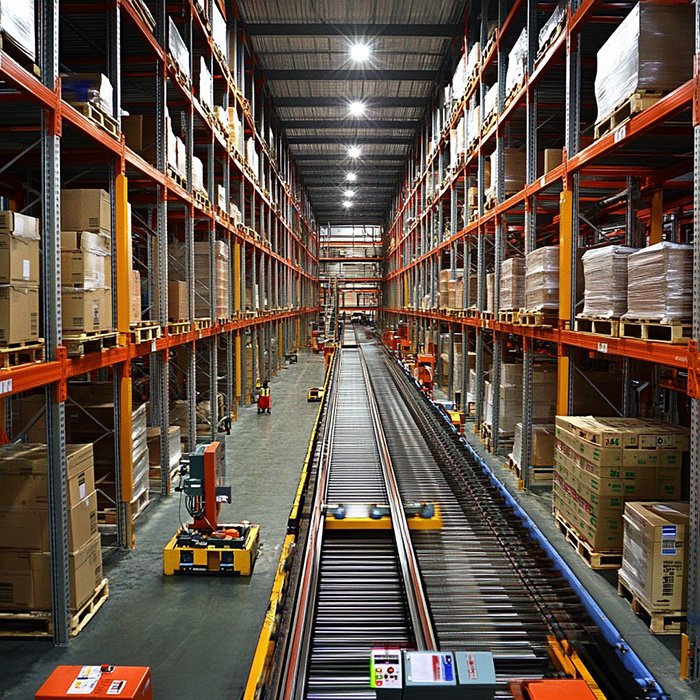

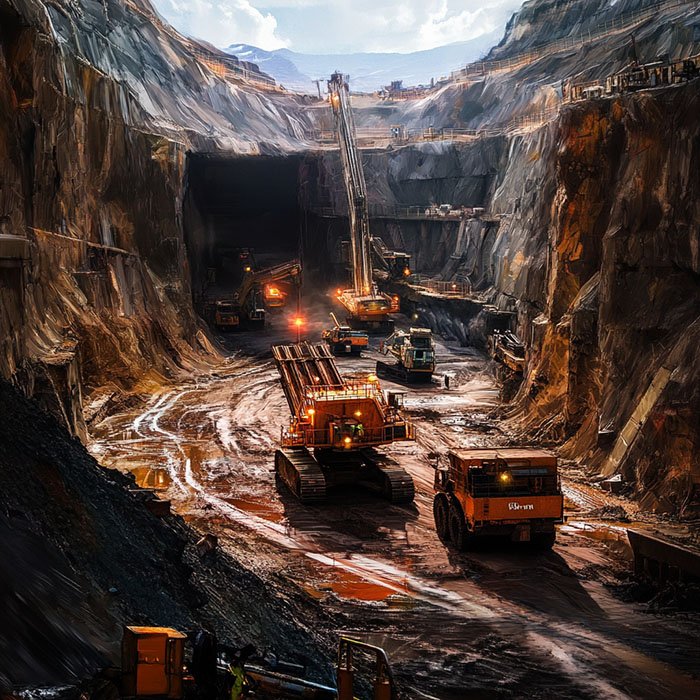

Laser distance sensor in construction is essential for a variety of tasks, including site surveying, building layout, structural alignment, and measuring heights or distances for installation of beams and columns. It is also used for excavation depth measurement, monitoring the position of formwork, and verifying the accuracy of walls and foundations during construction. Additionally, laser distance sensors help in the precise measurement of distances for crane positioning, as well as for managing material handling and logistics, improving efficiency and reducing errors on construction sites.

1. Introduction: Transforming the Construction Industry

In construction, precise measurements and accurate monitoring are critical to ensuring safety and efficiency. Traditional manual measurements can be time-consuming and prone to errors. With advancements in laser sensor technology, construction companies now benefit from automated, non-contact measurements that enhance accuracy, productivity, and project management efficiency.

2. Structural Measurement and Layout

Accurate Distance Measurement:

Laser distance sensor module enable engineers to measure distances between construction points with high precision. This allows for error-free structural layouts, reducing material waste and rework. Whether measuring the height of a building, the distance between pillars, or other dimensions, the sensors ensure consistency throughout the construction phase.

Alignment of Structures:

During construction, laser sensors help align columns, beams, and walls by providing real-time feedback. This ensures that all structural elements are placed accurately according to design specifications, improving both stability and aesthetics.

3. Monitoring Structural Health and Stability

Real-Time Monitoring of Deformation:

Laser distance sensor in construction continuously monitor critical structures for signs of deformation or movement. For example, in bridges and large buildings, even slight shifts can indicate underlying issues. Real-time monitoring allows for proactive maintenance, preventing costly repairs or accidents.

Monitoring Settling and Subsidence:

Throughout construction and after completion, foundations may experience settling. Laser sensors monitor subsidence to ensure that settling occurs within acceptable limits. This is particularly important in large-scale projects and areas prone to soil movement.

4. Safety Management during Construction

Obstacle Detection for Cranes and Lifting Equipment:

laser distance sensor in construction are integrated into cranes and hoisting equipment to detect nearby objects and ensure safe operations. This minimizes the risk of accidents caused by collisions with structures or equipment.

Worker Safety in Hazardous Areas:

In areas with limited visibility or hazardous conditions, laser sensors detect the proximity of workers and equipment, triggering alarms if they come too close to danger zones. This improves on-site safety and reduces the risk of injury.

5. Intelligent Site Management and Digital Twin Applications

BIM (Building Information Modeling) Integration:

Laser sensors collect real-time measurement data, which can be integrated with BIM systems. This provides accurate, up-to-date models of the project throughout its lifecycle, from planning to post-construction.

Digital Twin for Predictive Maintenance:

Using laser sensors, digital twin models can simulate real-time conditions and predict maintenance needs. This enhances the management of complex infrastructure projects and extends the lifespan of structures.

6. Case Study: Skyscraper Construction Monitoring

A construction company used laser distance sensors to monitor the vertical alignment of a 100-story skyscraper. By detecting any deviations from the original plan, the team could correct alignment issues immediately. The sensors also monitored wind-induced sway and foundation settling, ensuring the building met safety standards upon completion.

Conclusion: Redefining Construction with Laser Sensors

Laser distance sensor in construction provide the construction industry with innovative tools for improving measurement accuracy, monitoring stability, and enhancing safety. As construction projects become more complex, laser sensors will play an increasingly important role in achieving digital transformation and sustainable development.