産業オートメーション用RS485レーザー距離センサー

現代の産業環境では、自動化、位置決め、安全監視、プロセス制御のために、正確で安定した距離測定が不可欠です。工場のコネクテッド化とインテリジェント化が進む中、従来の短距離センサーや民生グレードのセンサーではもはや十分ではありません。そこで rs485レーザー距離センサー は、産業オートメーション・システム全体で好まれるソリューションとなっている。.

rs485レーザー距離センサーは、その長い通信距離、強力な干渉防止能力、および産業用制御プロトコルとの互換性により、製造、物流、ロボット工学、およびスマート・インフラストラクチャ・プロジェクトで広く使用されています。多くのアプリケーションにおいて、エンジニアは特に 産業用rs485レーザー距離センサー 連続的な負荷や過酷な環境条件下でも確実に動作する。.

RS485レーザー距離センサーとは

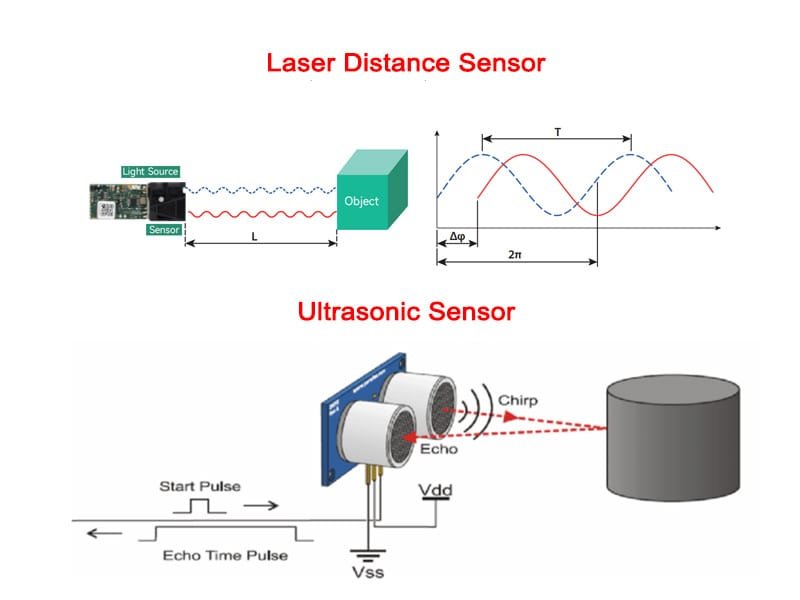

rs485レーザー距離センサーは、位相シフトや飛行時間技術などの光学原理を使用して、センサーとターゲット間の距離を計算するレーザーベースの測定装置です。測定されたデータは、産業用制御システムで広く採用されているRS485通信インターフェースを介して送信されます。.

USBやTTLインターフェースに比べ、RS485は長距離で安定した通信ができるように設計されています。このため、RS485レーザー距離センサーは、制御キャビネットが測定ポイントから遠く離れている可能性のある工場、倉庫、屋外設備に特に適しています。.

産業用システムでRS485通信が好まれる理由

RS485通信は、産業用距離測定に理想的ないくつかの技術的利点を提供します。.

主な利点のひとつは、伝送距離が長いことです。RS485信号は、信号の大幅な劣化なしに数百メートルの伝送が可能であり、これは大規模なオートメーションシステムには不可欠です。この利点は、特に 長距離rs485レーザー距離センサー 物流センター、スマート倉庫、インフラ監視プロジェクトなど。.

もうひとつの重要な利点は、電磁干渉に対する強い耐性である。産業環境には、電気的ノイズを発生するモーター、インバーター、ハイパワー機器などがしばしば存在します。RS485は差動信号を使用しているため、rs485レーザー距離センサーは電気的ノイズの多い環境でも安定した通信を維持することができます。.

高精度で安定した測定性能

正確さと再現性は、工業計測に不可欠です。A 高精度レーザー距離センサー は、一貫性のある正確な距離データを提供することができ、システムの信頼性と制御精度に直接影響します。.

最新のレーザー距離センサーは、短距離から中距離でミリメートルレベルの精度を達成し、表面の反射率や周囲光の条件が変化しても安定した性能を維持することができます。自動化された生産ラインでは、このレベルの精度が物体の位置決め、レベル検出、寸法検査などのタスクをサポートします。.

継続的なモニタリングが必要なアプリケーションでは、ピーク精度よりも安定した測定出力の方が重要な場合が多くあります。RS485通信により、距離データはデータ損失や不安定性なく、PLCやコントローラに確実に送信されます。.

PLCおよびModbus RTUシステムとの統合

エンジニアがrs485レーザ距離センサを選ぶ主な理由の1つは、PLCや産業用コントローラとのシームレスな統合です。RS485 は、産業オートメーションで使用される主流の PLC プラットフォームのほとんどでサポートされています。.

多くのデバイスがサポートしている レーザー距離センサー 通信により、標準Modbusレジスターを通して測定値の読み取り、パラメーターの設定、センサーの状態監視が簡単に行えます。これにより、システム統合が簡素化され、開発時間が短縮されます。.

Modbus RTU over RS485では、複数のセンサーを同じ通信バスに接続することができます。このアーキテクチャは、自動生産ライン、ロボットシステム、集中監視プラットフォームなどで広く使用されています。.

産業オートメーション・アプリケーション

rs485レーザー距離センサーは、信頼性と精度が重要な産業オートメーションシナリオに広く適用されています。.

製造環境では、センサは位置フィードバック、材料レベル測定、自動品質管理に使用されます。産業用rs485レーザー距離センサーを使用することで、高温、埃っぽい、振動の多い環境下でも安定した動作が保証されます。.

ロジスティクスや倉庫管理では、長距離距離センサがパレット位置の検出、スタック高さの測定、自動保管・検索システムのサポートに役立ちます。長距離rs485レーザ距離センサは、複雑な配線や信号リピータなしで、大規模施設でのデータ収集の集中化を可能にします。.

ロボティクスとスマート機器

ロボットシステムは、ナビゲーション、アライメント、障害物回避タスクを実行するために、正確な距離フィードバックに大きく依存しています。RS485レーザ距離センサは、複数のセンサが共有バス上で通信できるようにしながら、信頼性の高い測定データを提供します。.

移動ロボットや無人搬送車では、コンパクトなセンサ設計とRS485通信を組み合わせることで、配線の複雑さが軽減され、システムの安定性が向上します。高精度のRS485レーザー距離センサーは、ロボットがダイナミックな環境で正確な動作決定を行うのに役立ちます。.

スマートインフラと屋外アプリケーション

ファクトリーオートメーションにとどまらず、レーザー距離センサーはスマートインフラプロジェクトでますます使用されるようになっている。アプリケーションには、交通管理システム、建設モニタリング、構造物の変位測定などがある。.

RS485通信により、信頼性の高いデータ伝送を維持しながら、制御室から離れた場所にセンサを設置することができます。このため、rs485レーザー距離センサーは、長いケーブル配線が避けられない橋梁、トンネル、大規模輸送施設に適しています。.

RS485レーザー距離センサーの正しい選び方

適切なrs485レーザー距離センサーの選択には、単に測定範囲や精度を比較するだけではありません。通信の安定性、プロトコルのサポート、耐環境性、長期信頼性も同様に重要です。.

エンジニアは、センサがModbus RTUをサポートしているかどうか、必要なボーレート、電源仕様を確認する必要があります。要求の厳しいアプリケーションの場合、実績のある産業用リファレンスを備えた高精度rs485レーザー距離センサーを選択することで、メンテナンスコストを大幅に削減することができます。.

結論

について rs485レーザー距離センサー は、現代の産業オートメーションやスマート制御システムの中核をなすコンポーネントとなっている。安定した通信、長距離伝送、高い測定精度の組み合わせにより、幅広い産業用途に適しています。.

製造、ロジスティクス、ロボット工学、インフラストラクチャの監視など、産業用レーザ距離センサは信頼性が高く、拡張性のある距離測定を提供します。オートメーションシステムが進化し続ける中、RS485ベースのレーザ距離センサは、信頼性が高く、広く採用されるソリューションであり続けるでしょう。.