Sensor láser de alcance vs Sensor láser de triangulación: Explicación de las principales diferencias

Los sensores de medición de corta distancia son esenciales para la automatización industrial moderna, especialmente en robótica, logística de almacenes, producción de semiconductores, agricultura inteligente e inspección de fábricas de alta precisión. Dos de las tecnologías de detección más utilizadas en este campo son los sensor láser de alcance y el sensor de triangulación láser (también conocido como sensor óptico de desplazamiento).

A primera vista, ambos sensores parecen adecuados para la detección a corta distancia. Sin embargo, su principios de funcionamiento, rango de medición, comportamiento de la precisión, requisitos de instalación, tolerancia ambiental e idoneidad de la aplicación son fundamentalmente diferentes.

Este artículo ofrece una comparación detallada a nivel técnico y de aplicación para ayudar a los ingenieros a determinar qué tecnología es la más adecuada para su proyecto.

1. Funcionamiento de cada sensor

1.1 Sensor láser de alcance (desplazamiento de fase o medición TOF)

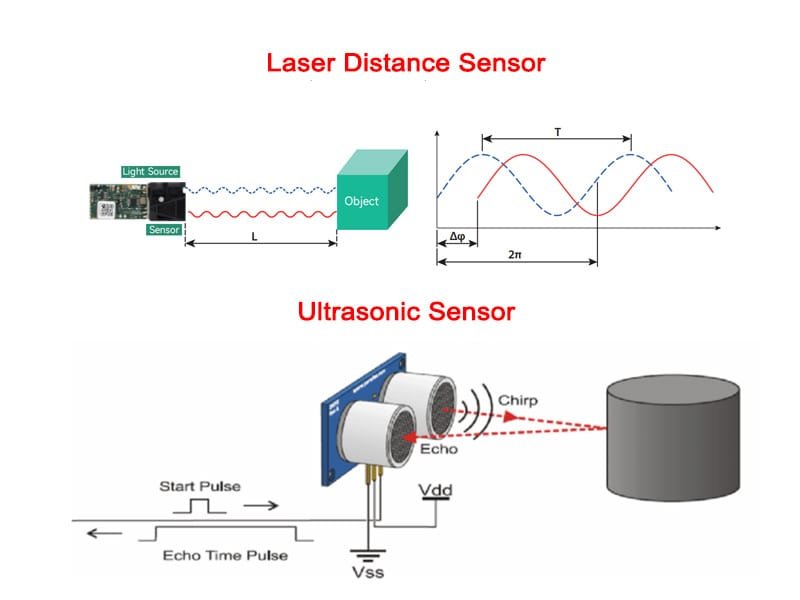

A sensor láser de alcance suele utilizar el desplazamiento de fase o el tiempo de vuelo (TOF) para medir la distancia.

Principio de funcionamiento:

- El sensor emite un haz láser modulado o pulsado.

- El haz reflejado vuelve al sensor.

- El sistema calcula la distancia a partir de la diferencia de fase o del tiempo de retorno.

Puntos fuertes:

- El cálculo de la distancia no depende de la geometría de la lente ni de la triangulación del haz

- Gran precisión incluso a varios metros

- Rendimiento constante independientemente del ángulo o el color del objeto

- Excelente estabilidad en exteriores y resistencia al ruido

- Funciona bien con objetivos oscuros, rugosos o poco reflectantes

Esto hace que el sensor láser de alcance ideal para situaciones industriales en las que la estabilidad y la fiabilidad son importantes.

1.2 Sensor láser de triangulación (desplazamiento geométrico óptico)

Un sensor de triangulación utiliza un principio óptico basado en la geometría.

Principio de funcionamiento:

- Se proyecta un punto láser sobre la superficie objetivo.

- El punto reflejado incide en un sensor CMOS/CCD/PSD a través de una lente.

- Al cambiar la distancia, el punto luminoso se desplaza en el detector.

- El sensor calcula la distancia en función del ángulo de desplazamiento.

Puntos fuertes:

- Resolución extremadamente alta a distancias muy cortas

- Excelente para detectar desplazamientos micrométricos

- Rápida velocidad de respuesta y alta sensibilidad

Limitaciones:

- Se ve muy afectado por el color, el ángulo y la reflectividad de la superficie

- Rango de medición típicamente corto (10-500 mm)

- Poca usabilidad en exteriores

- Requiere condiciones de montaje muy estables

Por ello, los sensores de triangulación son más adecuados para laboratorios y entornos de fabricación controlados.

2. Rango de medición y comparación de prestaciones

| Característica | Sensor láser de alcance | Sensor láser de triangulación |

|---|---|---|

| Alcance típico | 0,03 m - 200 m | 10 mm - 500 mm |

| Utilizable en objetivos oscuros/negros | Sí | A menudo inestable |

| Rendimiento al aire libre | Muy fuerte | Muy débil |

| Tolerancia angular | Alta | Bajo |

| Flexibilidad de la gama | Ancho | Muy estrecho |

| Precisión a micronivel | Medio | Extremadamente alto |

En sensor láser de alcance predomina cuando el alcance requerido es superior a 0,5 m o cuando la robustez ambiental es importante.

3. Precisión, estabilidad y resistencia ambiental

3.1 sensor láser de alcance

Precisión: normalmente ±1 mm

Frecuencia: hasta 30-100 Hz según el modelo

Ventajas:

- Estable en interiores y exteriores

- Resistente a la luz solar, el polvo, la niebla y los reflejos débiles

- Deriva mínima debida a los cambios de ángulo

- Funciona en metales, plásticos, tejidos, madera, etc.

- Ideal para objetos en movimiento

Esto la convierte en la mejor opción para automatización industrial, robótica, navegación AGV, máquinas de embalaje, sistemas de clasificación y detección de seguridad.

3.2 Sensor láser de triangulación

Precisión: extremadamente alta a corta distancia (nivel micrométrico)

Frecuencia: a menudo 1-2 kHz, buena para la detección de vibraciones sutiles

Limitaciones:

- Extremadamente sensible a las vibraciones de la instalación

- El punto de luz se distorsiona fácilmente en superficies brillantes/negras

- No soporta la luz ambiente intensa

- Alcance máximo limitado

El más adecuado para:

- Inspección de semiconductores

- Medición de la altura de la superficie

- Montaje de precisión

- Pruebas de desplazamiento en laboratorio

4. Idoneidad de la aplicación

sensor láser de alcance - Mejor para:

- Navegación AGV y AMR y anticolisión

- Posicionamiento del brazo robótico

- Automatización de almacenes / detección de carretillas elevadoras

- Detección del nivel de material

- Maquinaria agrícola inteligente

- Equipamiento compacto para exteriores

- Información a distancia para máquinas industriales

Su durabilidad y rango de medición lo hacen ideal para la ingeniería del mundo real.

Sensor de triangulación - Ideal para:

- Medición de microdesplazamientos

- Líneas de montaje de componentes electrónicos

- Análisis de planitud y espesor de superficies

- Detección de pequeños movimientos mecánicos

- Inspección de alta precisión en entornos limpios

La triangulación no tiene rival en cuanto a precisión de alcance ultracorto, pero no en cuanto a practicidad.

5. Resumen: ¿Cuál elegir?

Si su proyecto lo requiere:

Medición de corto alcance (0,1-80 m)

Estabilidad en el exterior

Detección de objetos oscuros

Robustez y flexibilidad

Si su proyecto lo requiere:

Inspección submilimétrica de superficies

Detección a muy corta distancia (<500 mm)

Iluminación controlada y montaje estable

En la mayoría de las aplicaciones industriales, especialmente en robótica, automatización y sistemas AGV.

el sensor láser de medición de distancias ofrece una eficiencia, fiabilidad y rendimiento a largo plazo superiores.