Why Modbus Laser Distance Sensors Are Preferred in Industrial Control Systems

Industrial control systems rely heavily on accurate, stable, and real-time measurement data to ensure efficient and safe operation. Among various distance measurement technologies, the Modbus Laser Distance Sensor has become a preferred choice for engineers, system integrators, and automation solution providers. Its widespread adoption is not accidental but driven by clear technical and practical advantages in modern industrial environments.

This article explains why Modbus laser distance sensors are increasingly used in industrial control systems and how they address the challenges faced in automation applications.

The Growing Demand for Reliable Distance Measurement in Industry

Modern factories and industrial facilities are moving toward higher levels of automation and digitalization. Production lines, robotic systems, automated warehouses, and smart logistics all require reliable distance feedback for precise control.

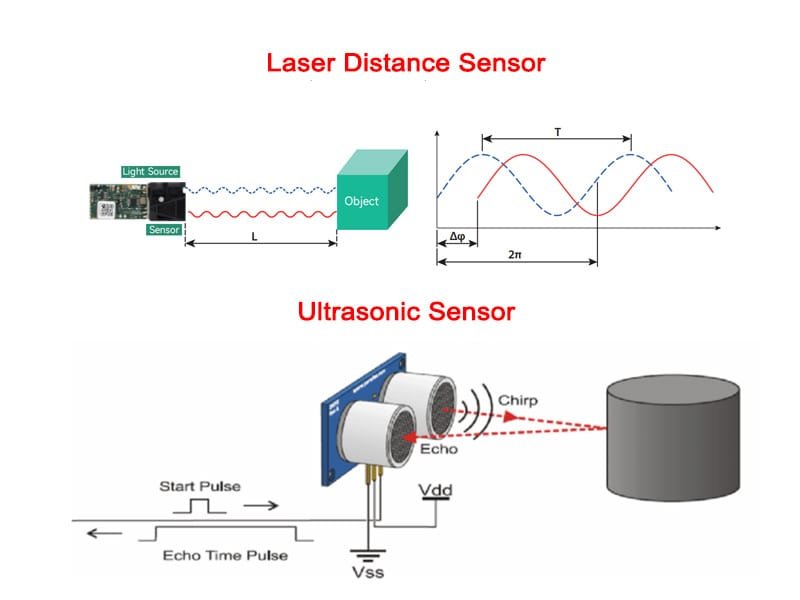

Traditional distance measurement solutions, such as ultrasonic sensors or analog-output devices, often face limitations in industrial environments. Electrical noise, long cable runs, signal attenuation, and integration complexity can negatively impact system stability.

As a result, industries are shifting toward digital communication-based sensors, and the Modbus Laser Distance Sensor has emerged as a robust and scalable solution for industrial control systems.

What Is a Modbus Laser Distance Sensor

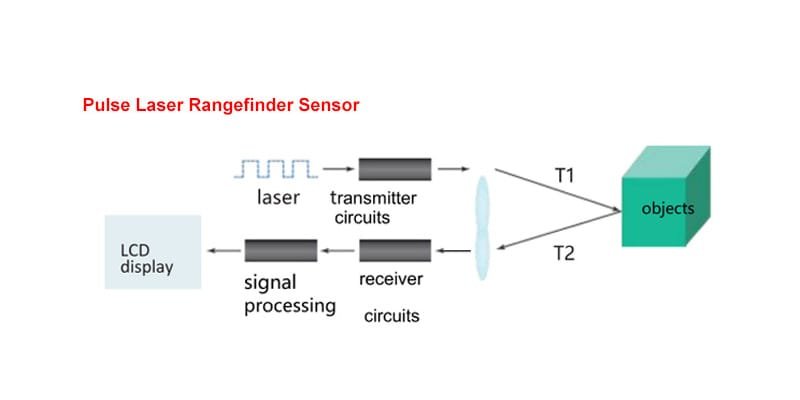

A Modbus laser distance sensor is a laser-based measurement device that uses the Modbus communication protocol, typically via RS485, to transmit distance data digitally. Unlike analog sensors that output voltage or current signals, Modbus sensors send structured digital data that can be directly read by PLCs, industrial controllers, and SCADA systems.

As a widely accepted industrial standard, Modbus RTU allows multiple devices to communicate over a single bus, enabling efficient system expansion and simplified wiring.

Why Modbus Communication Is Ideal for Industrial Control Systems

One of the main reasons Modbus laser distance sensors are preferred in industrial environments is the reliability of Modbus communication.

Industrial control systems often operate in electrically noisy environments, with motors, inverters, and high-power equipment generating interference. Analog signals are more susceptible to noise, while digital Modbus communication ensures data integrity over long distances.

Additionally, Modbus is universally supported by PLC brands and industrial control platforms. This makes a modbus laser distance sensor for PLC integration straightforward, reducing engineering time and minimizing compatibility risks.

High Accuracy and Stability for Precision Control

Precision is a critical requirement in industrial control systems. Laser-based distance measurement provides significantly higher accuracy compared to ultrasonic or mechanical sensors.

A high accuracy modbus laser distance sensor can achieve millimeter-level precision, making it suitable for applications such as positioning feedback, object detection, and dimensional control. Digital data transmission further ensures that accuracy is preserved without signal distortion during transmission.

Stable measurement performance over time is another advantage. Industrial-grade modbus laser distance sensors are designed to maintain consistent accuracy under temperature variations, vibration, and continuous operation.

Simplified System Integration and Maintenance

Ease of integration is a key consideration for system integrators. Modbus laser distance sensors can be directly connected to existing RS485 networks, allowing multiple sensors to operate on the same communication line.

An rs485 modbus laser distance sensor reduces wiring complexity and lowers installation costs, especially in large-scale industrial systems. Address-based communication allows engineers to manage and monitor multiple sensors efficiently.

From a maintenance perspective, digital communication enables easier diagnostics and troubleshooting. Sensor status, error codes, and configuration parameters can be accessed remotely through the control system, reducing downtime and maintenance costs.

Industrial Applications Driving Adoption

The flexibility of Modbus laser distance sensors makes them suitable for a wide range of industrial control applications.

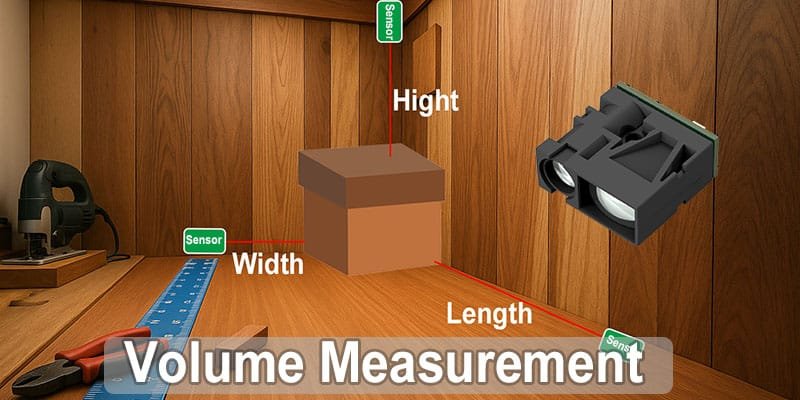

In automated conveyor systems, they provide accurate distance feedback for material positioning and spacing control. In robotic applications, sensors deliver real-time position data for arm movement and collision avoidance. Automated warehouses use laser distance sensors for pallet detection, height measurement, and storage optimization.

These use cases highlight why an industrial modbus laser distance sensor is becoming a standard component in modern automation solutions.

Scalability for Smart Factory and Industry 4.0 Systems

Industry 4.0 emphasizes data connectivity, interoperability, and scalability. Modbus laser distance sensors align well with these requirements by offering standardized communication and easy system expansion.

As production lines evolve or capacity increases, additional sensors can be integrated without major system redesign. This scalability makes Modbus-based sensors future-proof for smart factory applications.

Moreover, digital distance data can be seamlessly integrated into higher-level data analysis and monitoring systems, supporting predictive maintenance and process optimization.

Key Factors When Choosing a Modbus Laser Distance Sensor

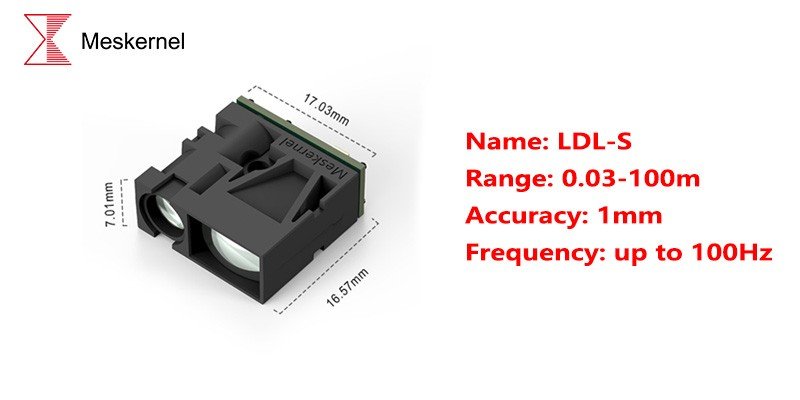

Selecting the right modbus laser distance sensor requires careful consideration of several technical parameters. Measurement range, accuracy, update rate, and communication compatibility are essential factors.

Environmental conditions such as dust, vibration, and ambient light should also be evaluated to ensure stable performance. Sensor size and mounting options are important when space is limited or installation flexibility is required.

By focusing on these criteria, engineers can select a sensor that meets both current and future system requirements.

Conclusion

The preference for Modbus Laser Distance Sensor solutions in industrial control systems is driven by their reliability, accuracy, ease of integration, and scalability. Digital Modbus communication ensures stable data transmission, while laser measurement technology delivers precise and consistent distance feedback.

As industrial automation continues to advance, modbus laser distance sensors will play an increasingly important role in enabling efficient, intelligent, and robust control systems.