Tunnel Surveying Transformed: Applications of Laser Distance Meter Module in Tunnels

As infrastructure development advances globally, tunnel construction is playing an increasingly critical role in transportation, mining, and urban planning. Accurate and real-time measurements during tunnel excavation are vital for safety and project success. The laser distance meter module has emerged as a reliable and efficient tool in tunnel surveying, offering high-precision, non-contact measurements in challenging environments.

What Is a Laser Distance Meter Module?

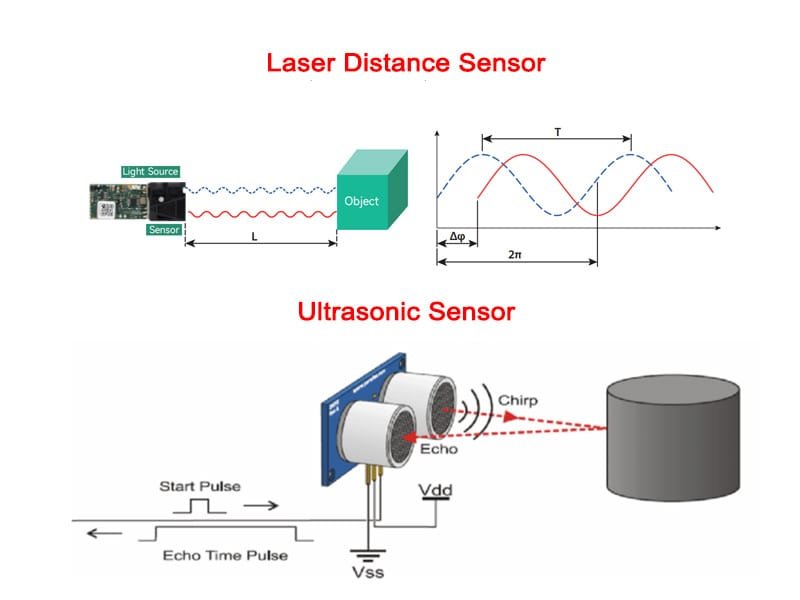

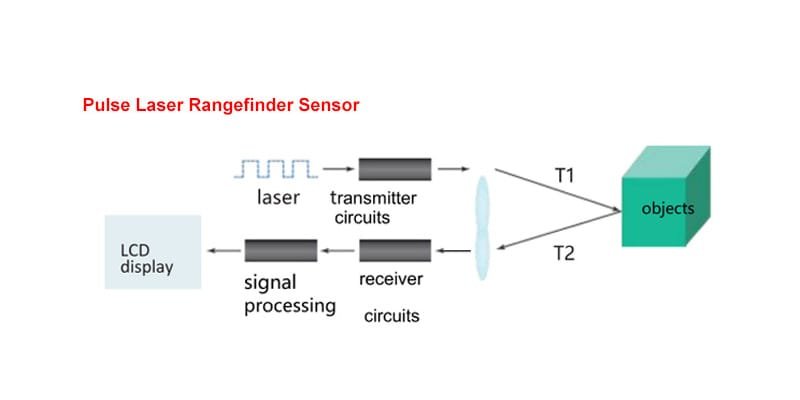

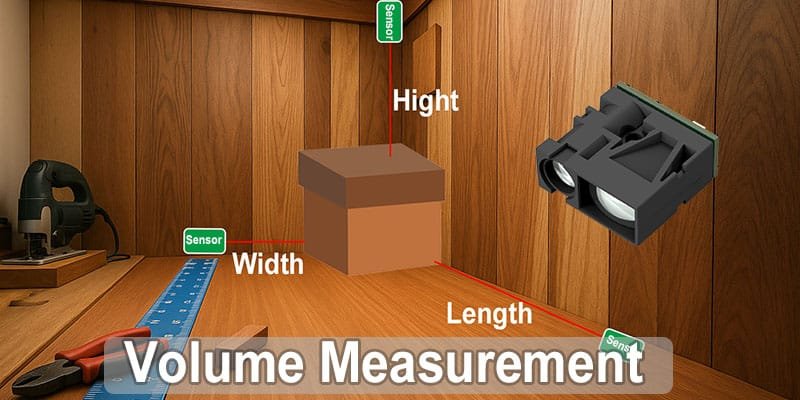

A laser distance meter module is a compact sensor that uses laser technology to measure distances accurately. Unlike traditional measurement tools, it uses either phase-shift or time-of-flight (ToF) technology to determine the distance between the sensor and a target surface. Its compact size, fast response time, and high accuracy make it ideal for embedded integration into industrial measurement systems.

Why Use Laser Distance Meter Modules in Tunnel Measurement?

Tunnels present harsh, dark, and often dusty environments where traditional measurement tools can struggle. The laser distance meter module offers multiple benefits for tunnel measurement tasks:

- High Precision: Capable of achieving millimeter-level accuracy even over long distances.

- Real-Time Monitoring: Continuous, real-time data output enables dynamic adjustments during excavation.

- Non-Contact Measurement: Improves safety and extends sensor life by reducing wear and tear.

- Compact Integration: Easily embedded into tunnel boring machines (TBMs) and automated survey platforms.

Applications in Tunnel Surveying

1. Tunnel Profile Monitoring

Laser distance meter modules are commonly mounted on rotary scanners or rail-guided systems to measure the tunnel cross-section profile. This ensures the excavation follows design specifications and alerts engineers to any structural deformations.

2. Excavation Face Distance Measurement

Engineers use laser distance sensors to measure the distance between the machine and the excavation face. This helps control cutting depth and ensures optimal excavation efficiency and safety.

3. Convergence Monitoring

In tunnels, monitoring wall convergence (i.e., inward movement due to pressure) is essential. Fixed laser modules continuously track critical points to detect potential collapses or instability early.

4. Segment Lining Installation

Accurate positioning during segment lining installation is critical for tunnel integrity. Laser distance modules assist automated systems in aligning and placing the segments precisely.

Case Study: Real-Time Tunnel Boring Machine (TBM) Monitoring

In a metro tunnel project in Southeast Asia, laser distance meter modules were integrated into the TBM’s guidance system. The sensors provided real-time feedback on the distance to the tunnel wall and face, improving precision and reducing downtime caused by manual measurements. The system operated reliably in low-light, high-dust conditions — a testament to the robustness of laser-based sensing technology.

Recommended Product: Industrial Laser Distance Sensor for Tunnel Measurement

For tunnel construction projects requiring stable and precise measurement under harsh environmental conditions, our industrial laser distance sensor is the ideal solution. Designed with a robust IP54/IP67-rated enclosure, it performs reliably in dusty, humid, and vibration-prone tunnel environments. The sensor supports a measurement range of 0.03 to 200 meters, with a high accuracy of 1–3 mm and a measuring frequency of 3–30 Hz, making it well-suited for real-time tunnel profiling, wall convergence monitoring, and equipment guidance. Whether integrated into tunnel boring machines (TBMs) or mounted on fixed monitoring systems, our sensor ensures consistent performance and long-term durability in demanding field applications.

Future Outlook

As smart infrastructure continues to evolve, laser distance meter modules for tunnel monitoring will become even more critical. Integrating these sensors into IoT systems and AI-driven analysis platforms will further enhance automation and safety in tunnel construction.

Conclusion

The laser distance meter module is revolutionizing how we approach tunnel measurement. Its precision, reliability, and adaptability to harsh environments make it a must-have tool in modern tunneling projects. As more industries move toward automation and smart construction, laser distance sensing technology will play a pivotal role in shaping the infrastructure of tomorrow.