Understanding Electrical Signal Communication in Modern Laser Distance Sensors

Introduction

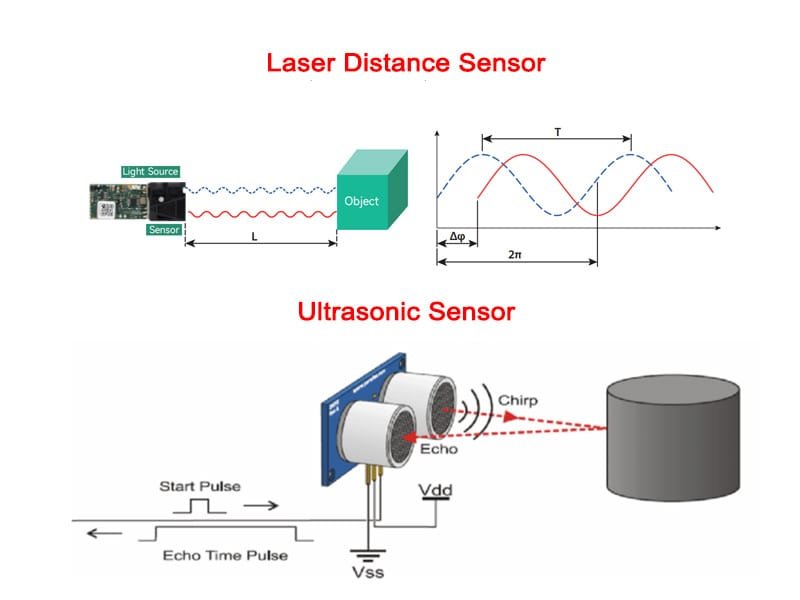

In modern industrial and automation systems, laser distance sensors are widely used for precise and non-contact distance measurement. While their optical technology determines accuracy, their electrical signal communication defines how effectively data is transmitted and interpreted. Understanding how analog, digital, and pulse signal communications work is critical for designing efficient and reliable laser sensing systems.

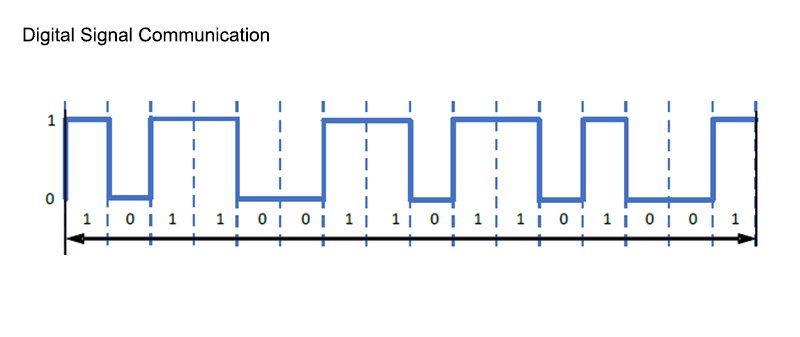

Digital Signal Communication in Laser Distance Sensors

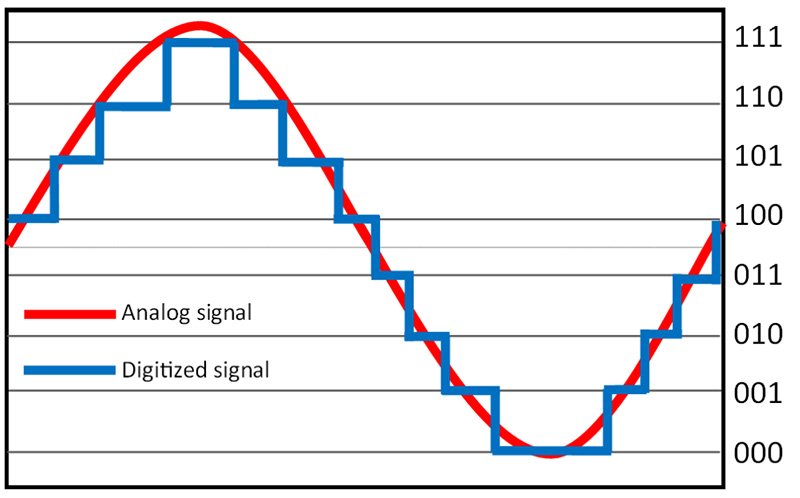

Digital signal communication forms the backbone of today’s smart sensor networks. These signals use two voltage levels — logic high (“1”) and logic low (“0”) — to transmit data between the sensor and its controller.

In the case of Meskernel’s LDL-T laser distance sensor, digital communication protocols such as RS485, UART, and TTL are used to transfer high-precision measurement data up to 100 meters with ±1 mm accuracy. This digital transmission ensures data integrity even in environments with strong electromagnetic interference, such as industrial automation lines or robotic control systems.

Unlike analog signals that can degrade over distance, digital communication offers noise immunity and reliable synchronization, allowing multiple laser sensors to operate simultaneously within a network.

Analog Signal Communication and Its Benefits

Although digital systems dominate, analog signal communication remains valuable in many industrial setups. Analog communication represents continuously varying voltages or currents corresponding to measured distances. A common format used in laser distance sensors is 4–20 mA current output, which converts distance into proportional current values.

Meskernel’s analog laser distance sensors, such as the LDL-S model, support both analog and digital outputs. The analog output allows seamless integration with PLC systems, analog control loops, and industrial equipment where smooth and continuous feedback is required. This versatility ensures backward compatibility with older systems while maintaining the precision expected from modern laser measurement technologies.

Moreover, analog outputs simplify real-time control. For instance, an operator can directly monitor the changing current to visualize distance variations without additional digital processing.

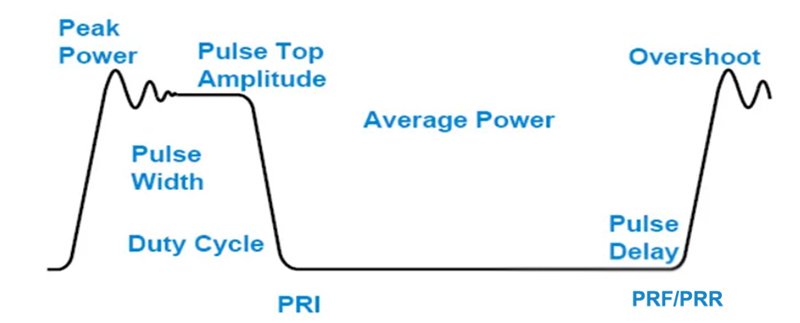

Pulse Signal Communication and Synchronization Control

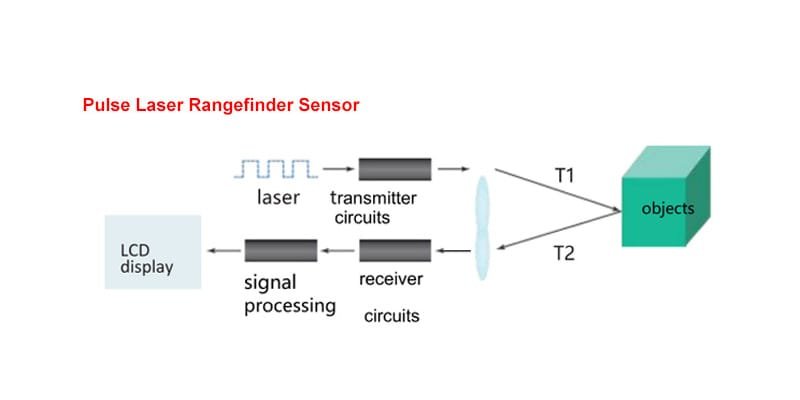

Pulse signal communication is another fundamental mechanism in modern sensor systems. It involves short bursts of voltage—called pulses—that represent timing or synchronization information rather than data values.

In laser distance sensors, pulse signals are often used to trigger measurements or coordinate multiple sensors operating within a shared environment. Each pulse defines when the measurement should start or when data should be sampled, helping to avoid cross-interference between devices.

This is particularly important in applications such as robotic arms, UAV navigation, or smart transportation systems, where sensors must maintain precise timing relationships. Pulse synchronization enables high-speed measurements while ensuring consistent accuracy across multiple sensing nodes.

Integration with Microcontrollers and Embedded Systems

Modern laser distance sensor modules are designed to interface easily with popular microcontrollers, including Arduino, ESP32, and Raspberry Pi. These platforms interpret electrical signals — digital, analog, or pulse — and convert them into actionable control logic.

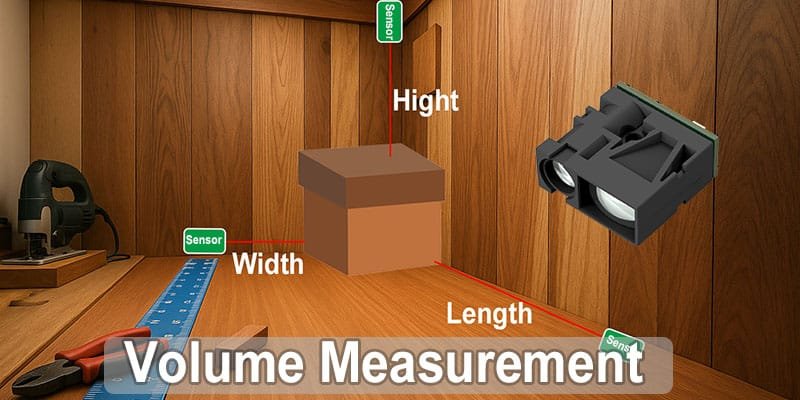

For example, a digital signal can instruct a robotic arm to stop when an object reaches a predefined distance, while an analog signal can continuously adjust actuator speed based on proximity. This flexibility makes laser distance sensors ideal for both industrial automation and IoT smart devices.

Through serial interfaces like UART, RS485, or I2C, engineers can build scalable sensor networks that combine high measurement accuracy with flexible communication options.

Applications of Electrical Signal Communication in Laser Sensors

The diverse communication methods of laser distance sensors allow their deployment in a wide range of industries:

- Industrial Automation: Position detection, conveyor monitoring, and process control.

- Logistics & Warehousing: Height measurement, pallet detection, and object counting.

- Smart Agriculture: Automated equipment positioning and growth measurement.

- Robotics & UAV Systems: Distance sensing, collision avoidance, and navigation mapping.

Each application benefits from the proper combination of analog, digital, and pulse communication methods, which enhance stability and precision.

Advantages of Signal Flexibility

By supporting multiple communication formats, Meskernel’s laser distance sensors deliver unmatched flexibility.

- High Reliability: Digital protocols like RS485 and UART ensure low latency and strong anti-interference ability.

- Easy Integration: Analog 4–20 mA outputs allow plug-and-play connection with legacy systems.

- Scalability: Pulse control enables synchronized operation among multiple sensors.

This design philosophy helps engineers optimize system performance while minimizing wiring complexity and communication loss.

Future Trends in Sensor Communication

As industrial systems evolve toward the Industrial Internet of Things (IIoT), electrical signal communication will continue to merge with wireless and networked protocols such as Bluetooth, Ethernet, and Wi-Fi.

Next-generation laser distance sensors are expected to integrate multi-protocol support, enabling hybrid communication that seamlessly transitions between wired and wireless environments.

Meskernel is committed to developing such smart sensors that balance precision, compatibility, and connectivity — the three pillars of modern sensing innovation.

Conclusion

Electrical signal communication — whether analog, digital, or pulse-based — is the invisible bridge between a laser distance sensor and the devices it serves.

It ensures that the data captured by precise optics can be accurately transmitted, analyzed, and acted upon.

By mastering these communication techniques, engineers can fully unlock the power of high-accuracy laser distance sensors, bringing new levels of intelligence and efficiency to automation, robotics, and industrial measurement systems.