How High Accuracy Laser Sensor Improve Industrial Automation Accuracy

In today’s fast-moving industrial environment, automation systems demand not only efficiency but also exceptional accuracy. From robotic control to logistics, from smart farming to material handling, precision measurement plays a vital role in every process. This is where a high accuracy laser sensor proves indispensable.

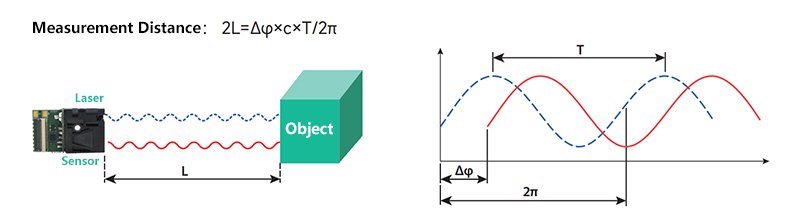

Our laser sensors utilize phase-shift distance measurement technology, setting them apart from traditional methods such as triangulation. While triangulation offers excellent precision in very short ranges, its effectiveness drops dramatically beyond a few meters. In contrast, phase-based laser distance measuring devices are capable of reaching much longer distances—up to 80 meters—with reliable accuracy, typically within ±1mm.

What Makes Phase-Shift Laser Sensors Different?

Triangulation sensors work by calculating the angle of reflected light to determine distance. While highly accurate at short ranges, this method becomes unstable over longer distances or in environments with dust or reflections.

Phase-shift sensors, on the other hand, emit modulated laser signals and compare the phase difference between emitted and received waves. This allows for stable, accurate measurements across longer distances with minimal influence from ambient light or surface reflectivity.

Although phase-shift sensors may not reach the sub-millimeter precision of triangulation in short-range applications, their long-range capability and ±1mm accuracy make them ideal for most industrial automation systems.

Applications in Industrial Automation

Here are some real-world use cases where our high accuracy laser sensors, especially distance measuring modules, bring tremendous value:

1. Industrial Robots and Automated Arms

Precise distance feedback is essential for robotic arms assembling parts or welding. A laser range module ensures components are correctly aligned, reducing production errors.

2. Automated Guided Vehicles (AGVs)

AGVs in warehouses require stable and responsive navigation. A laser distance measuring device provides long-range obstacle detection and path correction for smoother operation.

3. Material Level Detection

In industries like chemicals, food processing, and wastewater treatment, non-contact level monitoring is crucial. A high accuracy sensor can measure fill levels in large tanks safely and reliably.

4. Smart Logistics & Packaging

Conveyor systems use distance measuring modules to detect object positions for automated sorting, spacing, and quality checks.

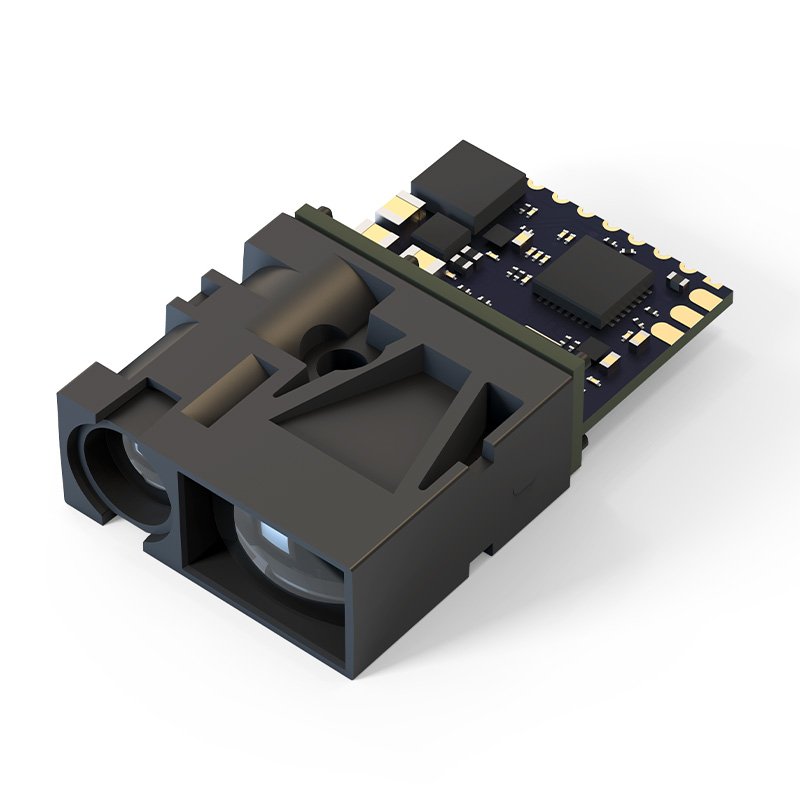

Why Choose Our LDL-T Laser Distance Measuring Device?

Our advanced LDL-T laser distance sensor is engineered for high-precision, long-range measurement in compact form. Here’s why it stands out:

- Measurement Range: 0.03 to 80 meters

- Accuracy: ±1mm

- Measuring Frequency: Up to 30Hz for real-time detection

- Laser Options: Green (510–550nm) and Red (610–690nm) for various lighting conditions

- Interfaces: Modbus, UART, RS232, RS485

- Platform Compatibility: Arduino, Raspberry Pi, ESP32, PLC

- Compact Design: Just 17.03×7.01×27.87mm, weighing only 3g

The LDL-T is not just another sensor—it’s a precision-engineered laser range module built for integration into advanced automation systems. Its phase-shift measurement technology delivers reliable results across a wide range of industrial environments, even when traditional sensors fail.

Final Thoughts

Industrial automation is only as reliable as the data it receives. In tasks where every millimeter matters, the high accuracy laser sensor becomes the backbone of intelligent decision-making. Whether you’re managing robotic movement, material flow, or equipment positioning, precision and range are non-negotiable.

With our LDL-T laser distance measuring device, you gain both. Designed with performance, size, and integration flexibility in mind, it empowers your automation projects with confidence and accuracy.

Looking to upgrade your automation system? Explore the LDL-T—an advanced distance measuring module for smart, scalable, and accurate solutions.