Analog Laser Sensor Designed for Reliable Industrial Distance Measurement

Overview

In modern industrial automation, stable and interference-resistant distance measurement is a key requirement across production lines, material handling systems, and process control environments. An analog laser sensor using a 4–20mA current loop has become one of the most reliable solutions for long-term, continuous distance monitoring.

Unlike purely digital sensors, analog signal transmission is widely recognized for its robustness in electrically noisy environments. A laser distance sensor 4-20mA converts distance data into a proportional current signal, ensuring accuracy over long cable runs and consistent performance in harsh industrial conditions.

Why 4-20mA Remains the Industry Standard

The 4–20mA current loop is a globally accepted signal standard in industrial automation. Compared with voltage-based outputs, current signals are far less sensitive to electromagnetic interference, voltage drop, and ground potential differences.

A current laser distance sensor analog operating at 4–20mA offers several practical advantages:

• Stable signal transmission over long distances

• Strong immunity to EMI and electrical noise

• Easy integration with PLCs, DCS, and industrial controllers

• Clear fault detection when current drops below 4mA

These features make analog laser sensors ideal for factories, outdoor installations, and continuous operation systems where reliability is critical.

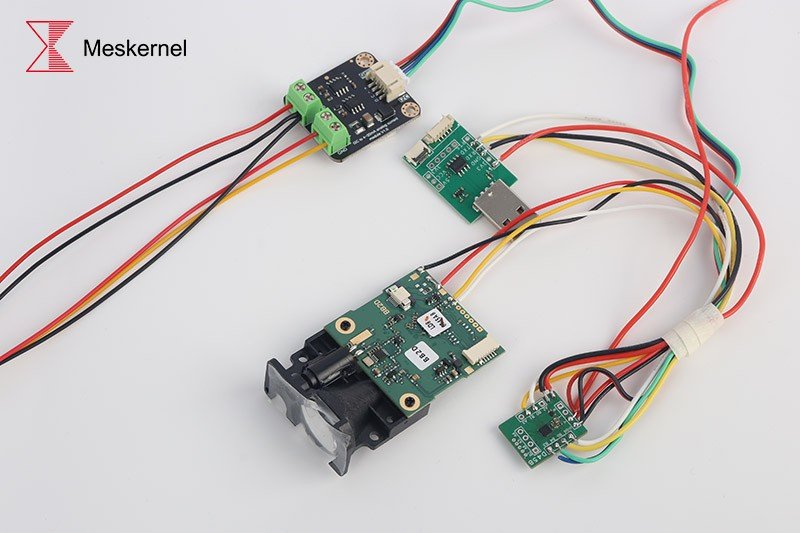

How an Analog Laser Distance Sensor Works

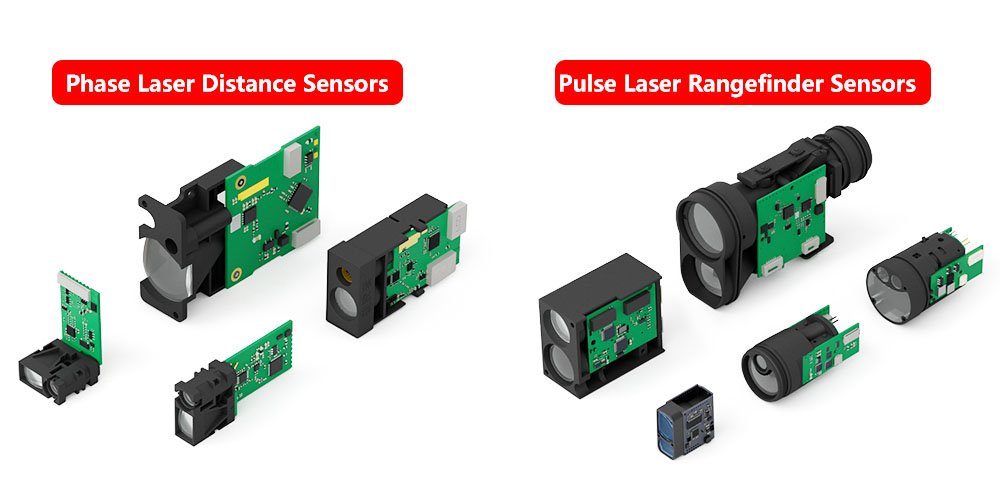

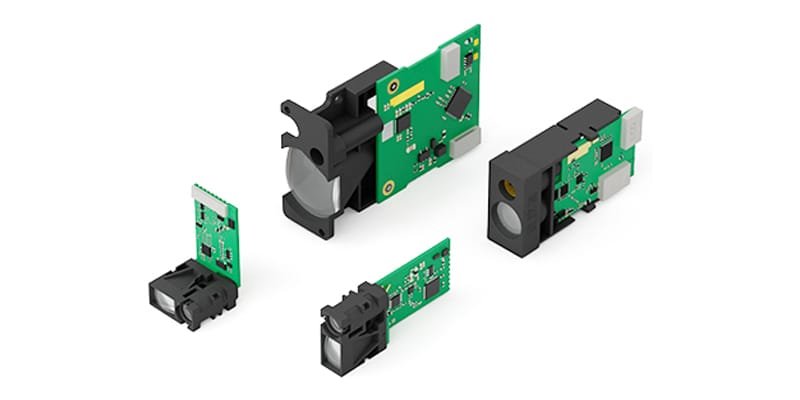

An analog laser distance sensor emits a laser beam toward a target surface and calculates distance based on reflected light using phase-shift or time-of-flight technology. The measured distance is then converted into a proportional analog current signal.

For example:

• Minimum distance → 4mA

• Maximum distance → 20mA

This linear relationship allows industrial controllers to easily interpret distance values without complex digital communication protocols. The result is fast, real-time feedback suitable for closed-loop control systems.

Key Advantages of Laser Distance Sensor Analog Output

A laser distance sensor analog output is especially suitable for applications where simplicity and reliability are more important than data packet complexity.

Key benefits include:

• Continuous real-time signal output

• Minimal signal delay

• Compatibility with legacy industrial systems

• Lower software integration requirements

• High resistance to harsh electrical environments

These advantages explain why analog laser sensors are still widely used even as digital interfaces continue to evolve.

Typical Applications of Laser Distance Sensor 4-20mA

Thanks to its stability and adaptability, a laser distance sensor 4-20mA is commonly used across many industries:

• Industrial automation and production lines

• Material level measurement in silos and tanks

• Conveyor positioning and object detection

• Crane and lifting system distance control

• Smart agriculture equipment positioning

• Industrial robotics and motion control

In many of these scenarios, analog output provides faster system response and higher long-term reliability than digital-only solutions.

Analog vs Digital Laser Distance Sensors

While digital laser sensors offer advanced data transmission, analog sensors continue to play a crucial role in industrial environments.

Analog laser sensor advantages:

• Better noise immunity

• Simpler system architecture

• Easier troubleshooting

• More stable long-distance transmission

Digital sensors excel in multi-parameter data and networked systems, but when the priority is continuous, real-time distance feedback, an analog output laser distance sensor remains a preferred choice.

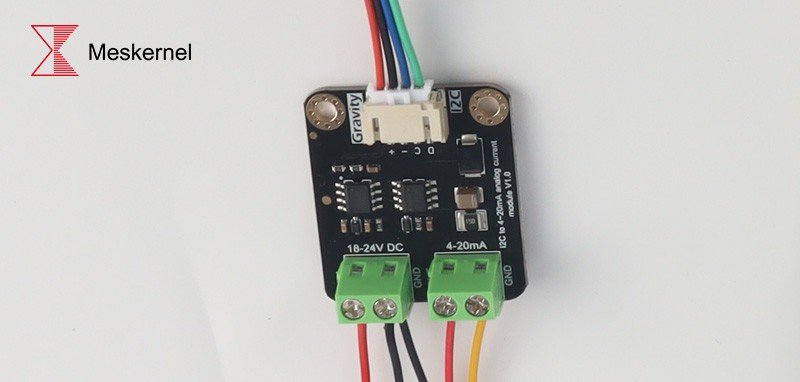

System Integration and Compatibility

A analog output laser distance sensor is designed for seamless integration with common industrial equipment, including:

• PLC control systems

• Industrial I/O modules

• SCADA systems

• Analog data acquisition cards

The standardized 4–20mA signal ensures compatibility across different brands and platforms, reducing integration time and maintenance costs.

Designed for Harsh Industrial Environments

Industrial environments often involve dust, vibration, temperature fluctuations, and electrical noise. An analog laser sensor is engineered to maintain measurement stability under these conditions.

With proper shielding, industrial-grade connectors, and robust internal circuitry, the sensor delivers consistent output even in demanding applications where digital communication may fail.

Future of Analog Laser Distance Sensors

Although industrial communication protocols continue to evolve, the demand for analog laser distance sensors remains strong. Their simplicity, reliability, and proven performance ensure they will continue to play an important role in automation systems worldwide.

For system designers and engineers seeking a dependable distance measurement solution, a 4-20mA laser distance sensor offers an optimal balance between accuracy, stability, and integration simplicity.

Conclusion

An analog laser sensor with 4–20mA output provides a reliable, industry-proven solution for precise distance measurement in automation and control systems. With strong anti-interference capability, easy integration, and continuous real-time output, a laser distance sensor analog output remains an essential component in modern industrial applications.