Laser Distance Sensors Transforming Forklift Safety and Efficiency

Overview

As industrial logistics becomes faster and more automated, forklifts face increasing demands for safety, efficiency, and intelligent operation. One of the key technologies enabling this transformation is the laser distance sensor forklift system. By integrating high-precision measurement sensors into material-handling equipment, modern forklifts can achieve enhanced collision prevention, accurate mast height monitoring, load positioning, and automated navigation support.

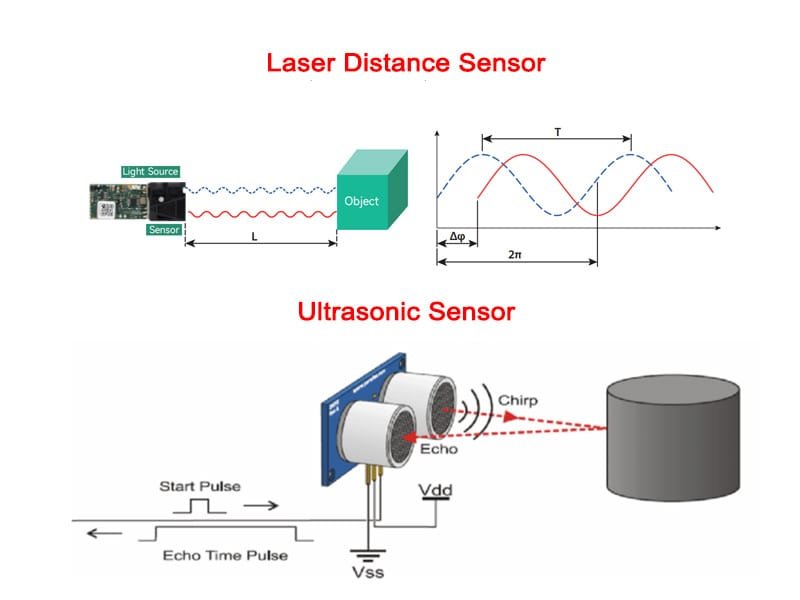

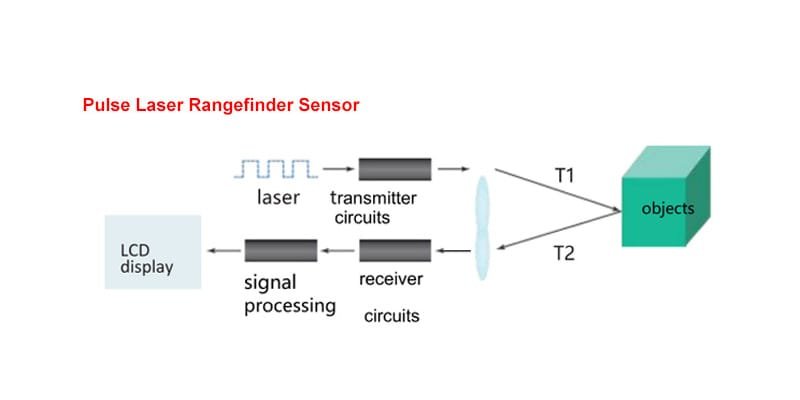

Many industrial companies are now upgrading from traditional ultrasonic sensors to laser-based systems due to their superior accuracy, longer range, and stability under varying light or environmental conditions. This article explains how laser distance sensors improve forklift performance and why manufacturers worldwide are adopting solutions such as the forklift laser distance sensor, the Forklift proximity laser sensor, and the Laser distance sensor for forklift mast height monitoring.

Why Forklifts Need High-Precision Laser Distance Sensing

Forklift operations frequently involve narrow aisles, heavy pallets, unstable ground, and fast loading cycles. A slight misjudgment in distance or height can lead to damaged goods, unbalanced loads, or safety risks for operators.

Laser distance sensors bring several advantages:

1. Accurate Positioning in Confined Spaces

Unlike ultrasonic sensors, laser systems detect objects and surfaces with millimeter-level accuracy. This helps operators make precise steering decisions even in tight warehouse aisles.

2. Reliable Detection in Complex Environments

Forklifts often work around reflective surfaces, plastic film, metal shelves, and mixed-light environments. Laser technology is less affected by these conditions, ensuring stable distance data.

3. Enhanced Collision Avoidance

A Forklift proximity laser sensor can detect pedestrians, vehicles, barriers, and pallets in real time. Early warnings significantly reduce the risk of workplace accidents.

4. Support for Autonomous or Semi-Autonomous Operation

More factories are transitioning to AGV and AMR forklifts. These systems rely heavily on high-precision distance data, where laser sensors are essential.

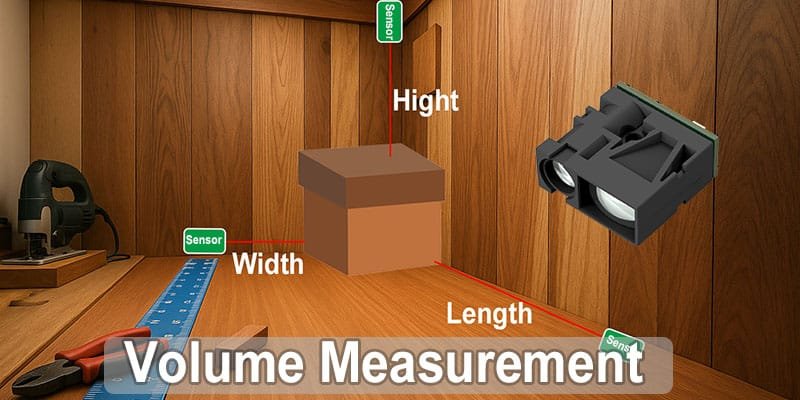

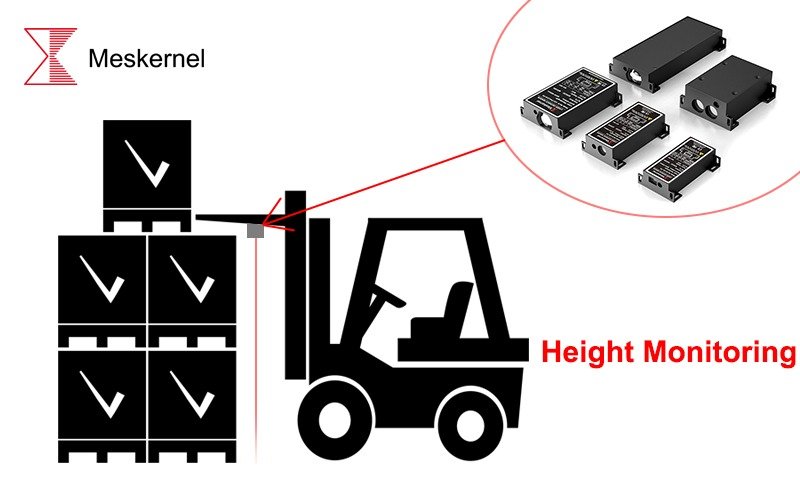

Laser Distance Sensor for Forklift Mast Height Monitoring

One of the most valuable applications is mast height monitoring. Traditional mechanical switches or low-precision sensors cannot provide accurate mast height feedback. Laser distance sensors solve this challenge.

Key benefits include:

Consistent Height Measurement

The mast movement is tracked continuously, ensuring operators know the exact fork height during loading and unloading.

Improved Load Stability

Accurate height feedback prevents tilting or loss of balance during pallet lifting.

Automated Leveling Support

Smart forklifts can automatically adjust to ideal loading heights using real-time laser distance feedback.

Reduced Product Damage

Precise measurements help place pallets correctly on racks without collision or scraping.

These advantages make the Laser distance sensor for forklift mast height monitoring widely adopted in warehouses, distribution centers, and manufacturing plants.

Forklift Proximity Laser Sensor for Safer Operations

Proximity detection is critical for warehouse safety. A forklift laser distance sensor can be mounted on the front, rear, or sides of the vehicle to create a protective detection zone.

Common functions include:

- Real-time obstacle detection up to several tens of meters

- Dynamic warning zones based on speed or direction

- Automatic braking or speed limitation on advanced forklifts

- Pedestrian detection in busy warehouse environments

This technology greatly improves operational safety and reduces accident-related downtime.

How Laser Distance Sensors Improve Forklift Productivity

Laser distance sensors not only enhance safety but also significantly boost work efficiency.

Faster Operation

Forklift operators can lift, position, and place pallets faster when accurate height and distance information is available.

Reduced Operator Fatigue

Real-time guidance minimizes manual guesswork.

Lower Maintenance Costs

Laser systems contain no moving parts, offering longer service life and less calibration.

Better Inventory Management

Accurate sensing ensures consistent pallet placement, improving warehouse orderliness.

Recommended Industrial Laser Distance Sensor for Forklift Applications

For companies looking to upgrade their forklifts, we recommend our industrial laser distance sensor, designed specifically for demanding warehouse and factory environments.

Key Features

- Measurement distance up to 100 meters

- High frequency up to 100 Hz

- Accuracy up to 1 mm

- Durable IP54 protective housing

- Red or green laser versions available

- Stable performance even in changing ambient light

This sensor offers excellent performance for forklift guidance, proximity detection, mast height monitoring, and automated material-handling applications. Its compact design and high speed make it suitable for both manual forklifts and automated AGV/AMR systems.

Whether your goal is to improve warehouse safety, enhance operational efficiency, or integrate advanced automation, this industrial laser distance sensor provides the reliability and precision required for modern logistics.