Introduction

Modern laser distance sensors have evolved far beyond basic optical devices. They are now integral parts of industrial automation, robotics, and IoT ecosystems, where efficient and reliable data communication is essential.

At the heart of these systems lie the hardware communication protocols — UART, SPI, I2C, CAN, and USB — which define how a laser sensor exchanges data with controllers, computers, and embedded systems.

Understanding these protocols not only helps engineers design better systems but also ensures that every measurement is transmitted accurately and on time.

UART Communication — Simple Yet Powerful

The Universal Asynchronous Receiver/Transmitter (UART) is one of the most widely used communication protocols in laser distance sensors. It operates with a simple two-wire system: TX (transmit) and RX (receive).

Meskernel’s LDL-T laser distance sensor, for example, supports UART for direct serial communication with Arduino, ESP32, or PLC systems. The main advantages of UART include:

- Ease of use: Requires minimal wiring and configuration.

- Asynchronous transmission: No clock line required.

- Wide compatibility: Works with almost all microcontrollers.

This simplicity makes UART ideal for low-power, short-distance applications such as distance feedback, automatic gate control, and mobile robotics. Engineers can easily send and receive measurement data using serial commands, making integration fast and efficient.

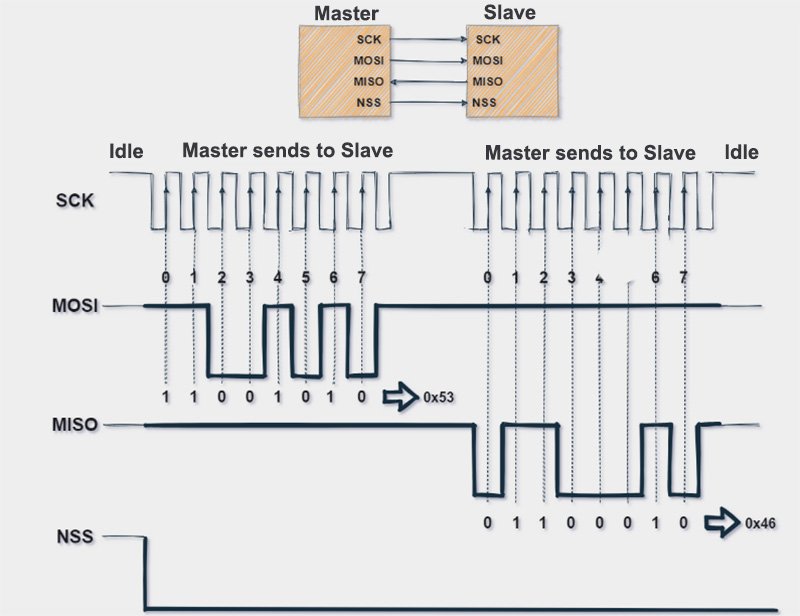

SPI Protocol — High-Speed and Full-Duplex Communication

The Serial Peripheral Interface (SPI) protocol is widely recognized for its high-speed, synchronous, and full-duplex communication.

In industrial laser measurement systems, SPI is used when fast data transfer and precise timing are critical. The protocol uses four main lines:

- MISO (Master In Slave Out)

- MOSI (Master Out Slave In)

- SCLK (Serial Clock)

- CS (Chip Select)

Through these connections, SPI enables the master controller—for example, an STM32 or Raspberry Pi—to communicate with one or multiple laser distance sensors simultaneously.

In the context of laser distance sensors, SPI Protocol provides low latency and high data throughput, making it ideal for applications that require real-time processing, such as:

- Multi-sensor laser triangulation systems

- Fast conveyor monitoring

- High-speed precision robotics

Because SPI Protocol transmits data continuously with clock synchronization, it minimizes transmission delay, ensuring consistent measurement feedback even at high data rates.

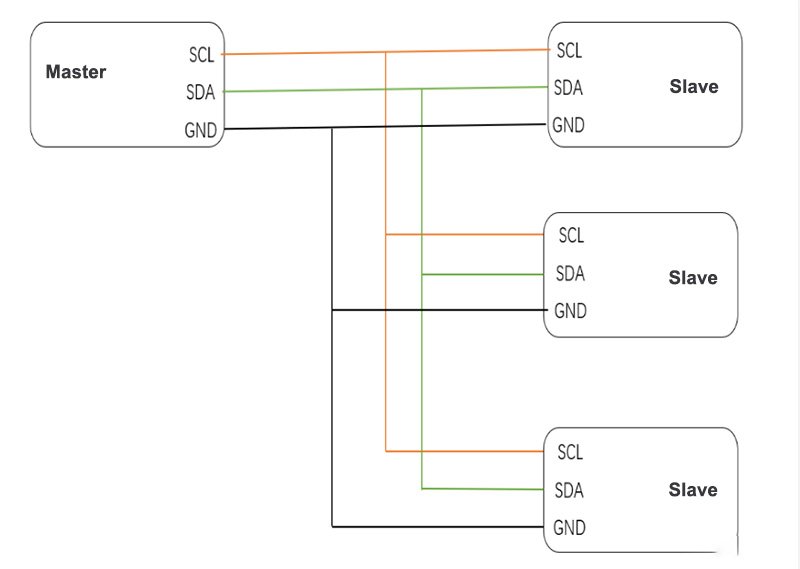

I2C Protocol — Compact and Multi-Device Communication (I2C Laser Distance Module)

The Inter-Integrated Circuit (I2C) protocol, developed by Philips, is a two-wire communication interface used for connecting multiple devices through only two lines: SDA (data) and SCL (clock).

I2C is particularly popular in compact embedded systems, where space and pin count are limited. Meskernel’s LDL-T and LDL-S laser distance modules can be adapted to work through I2C-based converters, allowing one controller to manage multiple sensors simultaneously.

Advantages of I2C communication in laser distance sensors include:

- Simple two-wire connection

- Multi-master and multi-slave capability

- Efficient short-range data transmission

In industrial or IoT environments, I2C laser distance module simplifies wiring and reduces PCB complexity. For example, a single microcontroller can communicate with several distance sensors to perform synchronized measurements, making it an efficient solution for robot navigation, smart factory logistics, and automated inspection systems.

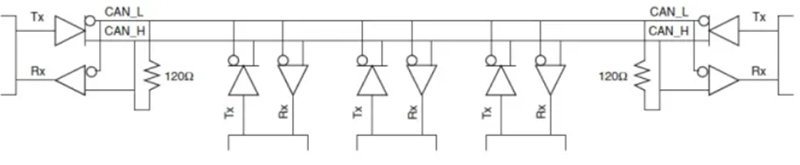

CAN Bus — Reliable Communication in Harsh Environments (CAN Laser Sensor)

The Controller Area Network (CAN) protocol was originally developed for automotive applications but has become a standard in industrial control systems.

It supports robust, differential, multi-node communication with strong noise immunity, ideal for long-distance data transmission and harsh environments.

When applied to laser sensor, CAN bus offers:

- High reliability and fault tolerance

- Data transmission up to 1 Mbps

- Cable length up to 1,000 meters (low-speed mode)

- Differential signaling (CAN_H and CAN_L) for anti-interference

These features make CAN laser sensor perfect for heavy-duty industrial systems, autonomous vehicles, and outdoor measurement scenarios where vibration, electromagnetic interference, or long cable runs could otherwise corrupt data.

For instance, integrating Meskernel’s LDL-T sensors via CAN communication ensures stable data transmission in large-scale factory systems or smart farming machinery.

USB Protocol — Universal and High-Speed Data Transfer (USB Laser Rangefinder Module)

The Universal Serial Bus (USB) remains the most common interface between computers and external devices.

In the case of USB Laser Rangefinder Module, USB interfaces provide plug-and-play connectivity, high-speed data transfer, and power supply through the same cable.

USB-based laser rangefinder modules are ideal for laboratory measurement, data logging, and R&D environments where engineers require direct access to sensor data on a computer.

For example, engineers can quickly connect a Meskernel sensor via USB and visualize distance readings in real time using custom software or serial terminal tools.

The USB laser rangefinder protocol supports:

- High bandwidth (up to 480 Mbps for USB 2.0)

- Hot-swapping and device auto-recognition

- Integration with PCs, laptops, and industrial computers

This convenience simplifies setup and testing, making USB laser rangefinder ideal for academic research, optical calibration, and prototyping.

Protocol Comparison and System Integration

Each communication protocol offers unique strengths, and choosing the right one depends on the application environment, distance, and system complexity.

| Protocol | Key Feature | Typical Use Case |

|---|---|---|

| UART | Simple, asynchronous | Short-distance control, robotics |

| SPI | High speed, full duplex | Real-time industrial measurement |

| I2C | Two-wire, multi-device | Compact IoT and embedded systems |

| CAN | Noise-resistant, long-distance | Automotive, industrial networks |

| USB | Plug-and-play, PC integration | Laboratory and R&D applications |

Meskernel designs its laser distance sensors with flexible interfaces — including UART, RS485, USB, and CAN — ensuring easy adaptation to different hardware ecosystems. This versatility allows engineers to select the communication type that best fits their automation or sensing platform.

Real-World Applications

Modern laser distance sensors that support multi-protocol communication are widely used in:

- Industrial Automation: Precision positioning, process monitoring, and feedback control.

- Smart Logistics: Distance-based pallet detection and object counting.

- Agricultural Equipment: Height control and navigation for harvesting robots.

- Robotics and UAVs: Real-time obstacle avoidance and mapping.

- Infrastructure Inspection: Bridge, tunnel, and pipeline monitoring.

In all these cases, reliable communication protocols ensure accurate data synchronization and low-latency response, which are critical to system safety and efficiency.

Advantages of Multi-Protocol Laser Distance Sensors

By supporting multiple hardware communication options, Meskernel’s sensors provide:

- Flexible integration with various controllers and platforms.

- High signal stability even in complex electromagnetic environments.

- Scalability for both small IoT projects and large industrial networks.

- Reduced wiring cost and simplified system design.

This makes them the preferred choice for developers and engineers seeking robust, long-term sensing solutions.

Future Outlook

As industries shift toward Industry 4.0, smart manufacturing, and autonomous systems, communication protocols are evolving to include hybrid designs — combining wired systems (UART, CAN) with wireless networks (Bluetooth, Wi-Fi).

Future laser distance sensors will feature auto-detect interfaces and adaptive communication that dynamically switch between protocols depending on system requirements.

Meskernel continues to develop next-generation laser measurement modules that integrate precision optics with intelligent communication frameworks, ensuring reliability, scalability, and data integrity across all environments.

Conclusion

Communication protocols such as UART, SPI, I2C, CAN, and USB are the invisible backbone of every laser distance sensor system.

They determine how efficiently distance data is transmitted, processed, and controlled across industrial and embedded networks.

By mastering these communication methods, engineers can unlock the full potential of smart sensing technology — achieving higher measurement accuracy, faster data exchange, and greater system compatibility.