The Role of Laser Ranging Module in Enhancing Industrial Production Efficiency

Industrial production is moving rapidly towards automation, digitalization, and smart manufacturing. At the center of this transformation lies advanced sensing technology, which ensures accuracy, efficiency, and reliability. Among these technologies, the Laser Ranging Module has become a key enabler for modern factories. By combining compact design with high precision, it provides industries with a powerful tool for real-time measurement, monitoring, and process optimization.

In this article, we explore how laser ranging modules enhance industrial efficiency, why they outperform traditional sensors, and how they are shaping the future of intelligent production systems.

Understanding Laser Ranging Module Technology

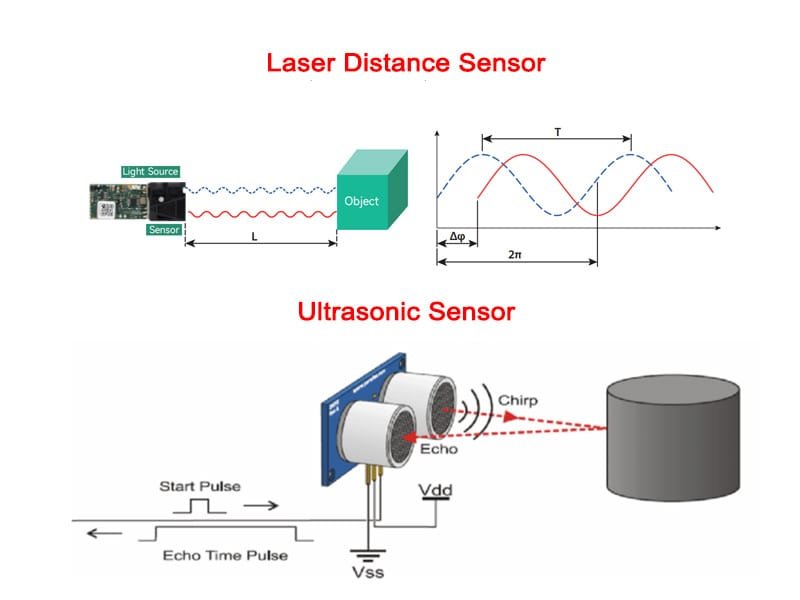

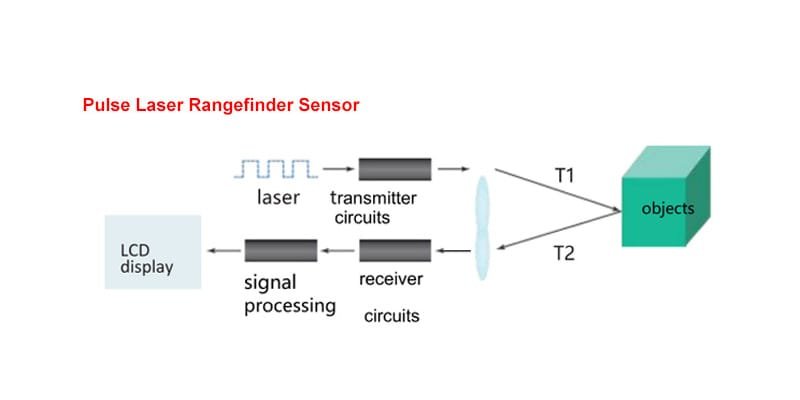

A Laser Ranging Module works by emitting a laser beam and calculating the time or phase difference between the transmitted and reflected signal. This method, known as laser measurement, delivers accurate and stable distance readings across short and long ranges.

Compared to ultrasonic or infrared sensors, a laser ranging sensor offers:

- Sub-millimeter accuracy for exact measurements

- Fast response times for dynamic environments

- Reliability in harsh industrial conditions

- Compact integration for space-limited machinery

This makes the laser measurement module one of the most reliable solutions for modern industrial applications.

Why Industries Choose Laser Ranging Modules

Accuracy and Consistency

In industries where errors can result in costly rework, precision is critical. A laser ranging sensor provides up to ±1mm accuracy, ensuring consistent results across production cycles.

Speed and Efficiency

Factories rely on fast operations. A laser measurement sensor module offers real-time feedback, allowing production lines to operate smoothly without delays caused by manual checks or inaccurate sensors.

Flexibility in Integration

Laser ranging modules are compact and versatile. They can be easily integrated into robotic arms, conveyors, CNC machinery, and automated inspection systems.

Applications of Laser Ranging Module in Industrial Production

Quality Control and Inspection

A laser ranging module plays an essential role in quality control by verifying dimensions, alignment, and product integrity. For industries like automotive and electronics, this ensures components meet precise specifications before reaching customers.

Robotics and Automation

Robots equipped with laser ranging sensors can handle tasks such as alignment, object detection, and material handling with greater efficiency. This reduces downtime and increases throughput.

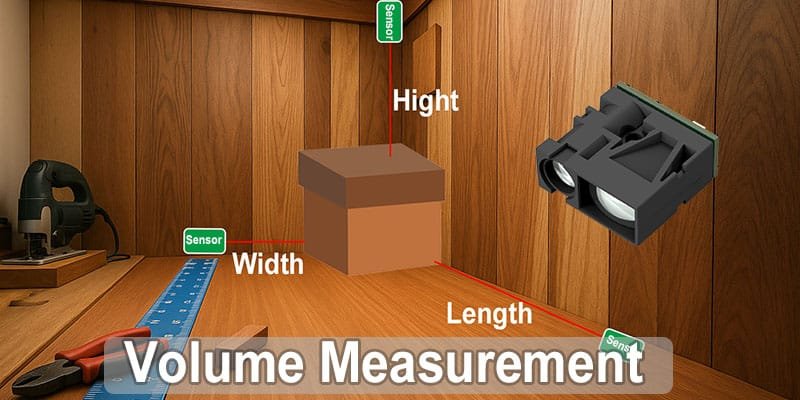

Inventory and Logistics Management

In warehouses, a laser measurement sensor module helps track inventory by monitoring object positions, pallet dimensions, and container levels. This enables real-time data collection, which enhances supply chain efficiency.

Machine Positioning and Calibration

Industrial machines require exact positioning to operate correctly. A laser ranging module assists in calibration, tool alignment, and system monitoring, ensuring smooth workflows and reducing human error.

Benefits for Industrial Production Efficiency

Reduced Waste and Costs

By ensuring accurate measurements, industries avoid material waste, defective products, and costly rework.

Improved Safety

A laser distance module can detect obstacles or hazards in production environments, enhancing worker safety and machine protection.

Increased Productivity

Automation systems equipped with precision laser ranging sensors minimize downtime, speed up inspection, and optimize workflows, leading to higher production output.

Data-Driven Manufacturing

When connected to IoT platforms, laser distance sensors provide continuous data for predictive maintenance, quality monitoring, and smart decision-making.

Case Example: Automotive Industry

In automotive manufacturing, even the smallest deviation in component dimensions can compromise safety. By integrating laser ranging modules into assembly lines, car manufacturers ensure millimeter-level precision in welding, part placement, and body alignment. This not only improves safety standards but also reduces production bottlenecks, ensuring vehicles reach the market faster.

Future of Laser Ranging Modules in Smart Factories

As industries adopt Industry 4.0, the role of laser ranging modules will expand further. Upcoming advancements include:

- Integration with AI for automated decision-making

- Miniaturization to fit into smaller robotic platforms

- Enhanced connectivity with 5G-enabled smart factories

- Higher precision and range for more demanding applications

These innovations will strengthen the role of precision laser ranging sensors as a foundation of future intelligent manufacturing.

Conclusion

The journey toward efficient, automated, and intelligent industrial production depends on accurate measurement and sensing technologies. A Laser Ranging Module provides exactly that — combining precision, speed, and reliability in a compact design. Whether in quality control, robotics, logistics, or machine calibration, these sensors are essential for boosting productivity and ensuring operational excellence.

For industries aiming to reduce costs, improve safety, and achieve greater efficiency, investing in a laser measurement module is no longer an option but a necessity. The future of industrial production will continue to be shaped by laser ranging sensors, paving the way for smarter factories worldwide.