Measurement Laser Sensor for the Mining Industry

Overview:

In the mining industry, measurement laser sensor are widely used for mine depth measurement, coal stockpile monitoring, equipment positioning, and safety surveillance. With high precision, non-contact measurement, and durable design, these sensors help mining enterprises achieve safe, efficient operations and reduce human errors and accidents.

Content:

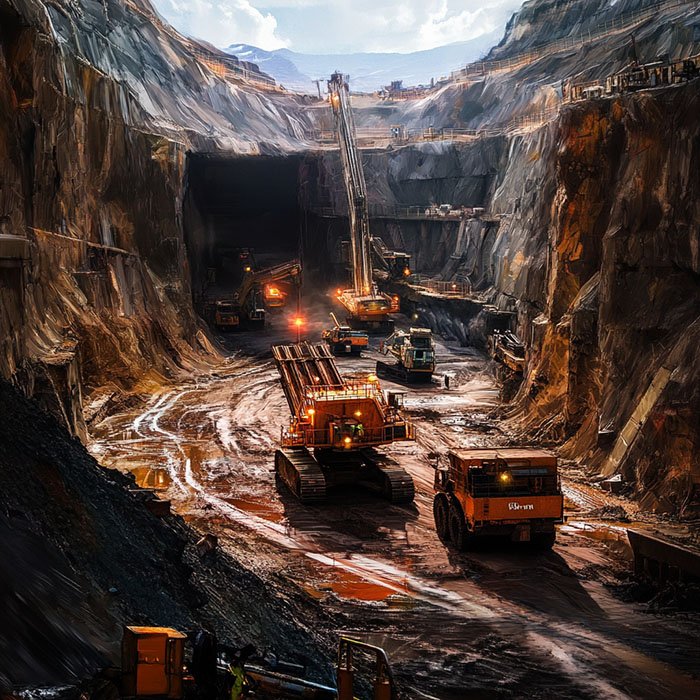

1. Introduction: Intelligent and Safe Management in Mining

Accurate measurement, automation, and safety monitoring are essential in mining operations. Traditional measurement methods are susceptible to environmental influences, and mine environments are often hazardous. Laser distance sensors offer precise, non-contact measurements, long-range monitoring, and robust designs, supporting intelligent management in mining.

2. Mine Depth and Space Measurement

Monitoring Mine Depth and Tunnel Length:

Laser sensors measure mine depth and tunnel excavation progress with high accuracy, ensuring precise distance control. Compared to traditional tape or rope methods, laser sensors are easier to operate, offer higher precision, and perform reliably in harsh environments.

Monitoring Tunnel Cross-Sections:

During excavation, laser sensors continuously monitor the cross-sectional dimensions of tunnels, ensuring compliance with design specifications. Their non-contact measurement capability reduces the risks of workers entering hazardous areas.

3. Monitoring Coal Stockpiles and Material Flow

Coal Stockpile Monitoring:

Measurement Laser Sensor installed atop coal silos monitor coal height and volume in real-time, helping managers keep track of inventory and avoid losses from shortages or overstocking.

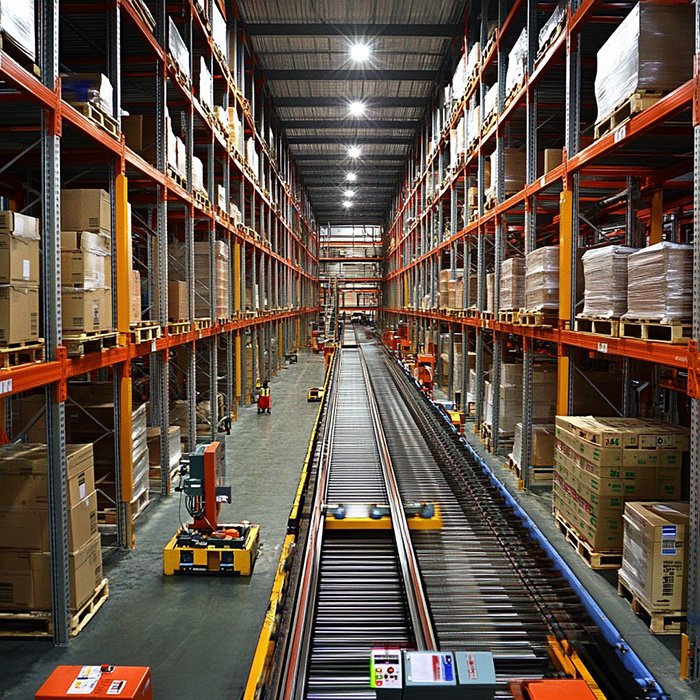

Material Flow Monitoring and Overload Alerts:

At critical conveyor belt points, laser sensors monitor the height of materials to prevent blockages or overloads that could cause equipment downtime or accidents. These sensors can also work with automated systems to facilitate intelligent loading and transportation.

4. Equipment Positioning and Navigation

Autonomous Mine Vehicle Navigation and Obstacle Avoidance:

Laser sensors enable autonomous mine vehicles to navigate by measuring the distance from obstacles, ensuring collision-free operation and improved efficiency. Even in GPS-limited underground environments, laser sensors ensure precise navigation and obstacle avoidance.

Positioning and Monitoring of Large Equipment:

Laser sensors assist in positioning mining equipment such as drills and excavators, ensuring operational accuracy and safety. The Measurement Laser Sensor can also transmit real-time status and location data to control centers for centralized management.

5. Safety Monitoring and Accident Prevention

Monitoring Roof Subsidence:

Roof subsidence is a significant risk in mining. Laser sensors continuously monitor roof height and provide alerts if subsidence exceeds safety thresholds, enabling timely reinforcement and preventing collapses.

Surveillance of Hazardous Areas:

In dangerous areas, laser sensors monitor the distance between isolation barriers and work zones to prevent unauthorized entry, ensuring site safety.

6. Case Study: Intelligent Mining Management

A large mining company implemented Measurement Laser Sensor for monitoring mine depth, roof subsidence, and autonomous vehicle navigation. The sensors provided real-time stockpile data and integrated with automated conveyor systems, ensuring continuous material supply and stable equipment operation. This system significantly improved operational efficiency and reduced risks associated with manual operations.

7. Conclusion: Driving Safety and Efficiency with Laser Sensors in Mining

Laser distance sensors offer precise, efficient measurement and safety management solutions for the mining industry. They improve the accuracy of excavation and equipment operations while reducing the likelihood of accidents. As mining automation progresses, laser sensors will continue to play a key role in promoting sustainable, safe, and efficient mining practices.

The integration of laser sensors in mining operations has enabled intelligent measurement and monitoring, supporting high-efficiency operations and safety. In the future, laser technology will further integrate with IoT and data analytics, driving innovation in mining management.